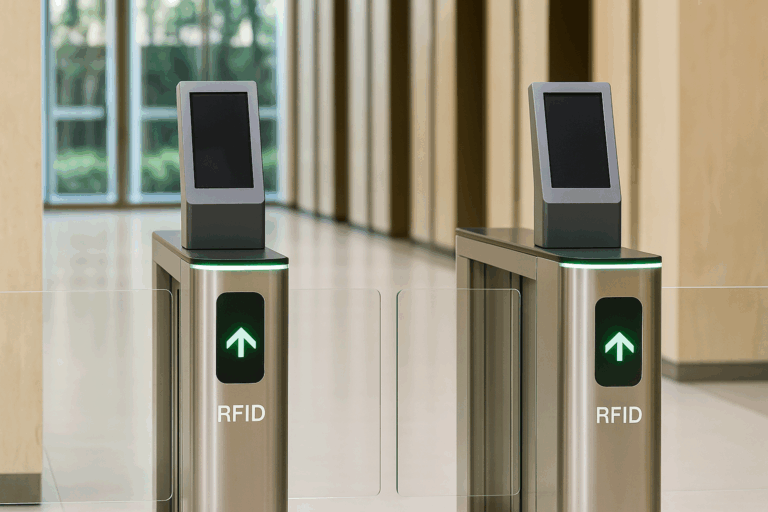

Have you ever wondered why RFID adhesive tags are becoming essential in modern operations? These small but powerful labels act as digital fingerprints, enabling real-time visibility and accuracy in asset and inventory management. With RFID adhesive tags, companies move beyond manual counts and barcodes, achieving 90%+ stock accuracy, faster replenishment, and tighter control from production to customer delivery.

In retail, this means fewer stockouts and more reliable omnichannel promises. In healthcare, it means safer medication dispensing and faster access to critical equipment. In logistics and manufacturing, it enables automation, sustainability, and cost reduction. By turning every item into data, RFID adhesive tags transform operations into ecosystems of precision and control — and that’s where CPCON leads as a global partner.

Table of Contents

ToggleWhat Are RFID Adhesive Tags and Why Do They Matter?

At their core, RFID adhesive tags are smart labels that combine a microchip and an antenna, embedded in a thin adhesive layer. Unlike traditional barcodes, which require line-of-sight scanning, RFID tags transmit data wirelessly to readers. This means hundreds of items can be identified in seconds, without manual intervention.

These adhesive tags act like digital fingerprints: each one carries a unique Electronic Product Code (EPC) that makes the tagged item instantly traceable across the supply chain. The adhesive format allows quick application on products, boxes, pallets, or equipment, adapting to different surfaces and operational needs.

Why they matter:

- Accuracy: real-time stock updates reduce human error and shrinkage.

- Speed: inventory counts that once took hours are completed in minutes.

- Visibility: end-to-end tracking improves replenishment, quality control, and compliance.

- Scalability: tags integrate seamlessly with ERP, WMS, and IoT platforms.

How RFID Adhesive Tags Reshape Retail Efficiency

In retail, success depends on knowing exactly what is in stock — and where. RFID adhesive tags turn this challenge into a competitive advantage by offering real-time inventory visibility. This means fewer lost sales, more accurate replenishment, and better use of working capital.

Strategic impacts in retail:

- Inventory accuracy above 90%: from warehouse to shelf, companies know what they really have.

- Omnichannel confidence: e-commerce, click & collect, and ship-from-store models rely on reliable data.

- Customer experience: faster checkouts and smart fitting rooms make shopping smoother.

How RFID Adhesive Tags Reshape Retail Efficiency

In retail, knowing exactly what’s in stock—and where—makes all the difference. RFID adhesive tags transform inventory visibility into a strategic asset by offering real-time tracking across stores, fulfillment centers, and distribution networks.

Strategic benefits for retail:

- Inventory accuracy rises dramatically, often exceeding 95%, compared to the 60–75% typical with barcode systems. RFID enables faster, more frequent cycle counts, leading to fewer stockouts and more confident replenishment.

- Reliable omnichannel capabilities—such as buy online/pick up in-store (BOPIS) or ship-from-store—become possible because data reflects actual stock, not an approximation.

- Seeing these gains in action: Zara, the fast-fashion leader, moved from doing inventory counts every six months to every six weeks once they implemented RFID. This shift enabled leaner inventories, more accurate demand forecasts, and faster turnaround.

Food & Beverage: Safety, Traceability and Sustainability

In the food industry, RFID adhesive tags go beyond inventory—they enable proactive safety, real-time traceability, and better waste control throughout the supply chain.

Why they matter in food & beverage:

- Rapid traceability and recall response: RAIN RFID tags track products from farm to shelf, recording batch, origin, and movement data. In case of contamination, affected goods can be quickly isolated based on RFID history. (Impinj)

- Waste reduction through precise expiry management: RFID-enabled visibility into production and expiry dates supports FEFO (first‑expire-first‑out) inventory rotation, reducing spoilage and overstocking. (Barcoding.com)

- Improved food safety compliance and supply chain transparency: Using RFID simplifies traceability and aligns operations with evolving regulations like FSMA 204, which demand end-to-end visibility. (Checkpoint Systems)

Logistics and Supply Chain: Real-Time Control with RFID Adhesive Tags

In logistics, RFID adhesive tags automate critical processes and provide end-to-end visibility. By replacing manual barcode scans, companies gain accuracy, speed, and sustainability in their daily operations.

Key impacts:

- Automated receiving and shipping, reducing human error.

- Real-time tracking of shipments, returnable containers, and pallets.

- Lower costs through labor efficiency and less paper-based documentation.

Manufacturing: Efficiency and Quality with RFID Adhesive Tags

In manufacturing, RFID adhesive tags ensure visibility from raw materials to finished goods. Each component receives a digital identity, allowing managers to track its movement, assembly, and quality status.

Strategic impacts:

- Real-time tracking of work-in-progress reduces downtime and bottlenecks.

- Automated quality checks create a digital history for each product, supporting audits and compliance.

- Faster root-cause analysis when defects appear, minimizing recalls and warranty costs.

Challenges and ROI of RFID Adhesive Tags

Like any technology, RFID adhesive tags face adoption barriers. The main concerns are cost, environmental conditions, and system integration. But when addressed strategically, these challenges quickly turn into measurable returns.

Key challenges:

- Initial investment: Tags, readers, and integration require upfront capital. However, automation and error reduction shorten payback cycles.

- Environmental factors: Metals, liquids, and extreme temperatures can reduce read performance, requiring specialized tag designs.

- System integration: Aligning RFID events with ERP, WMS, or MES demands planning, but ensures long-term scalability.

Sustainability: Reducing Waste with RFID Adhesive Tags

Sustainability is no longer optional. Companies across sectors are under pressure to cut waste, optimize resources, and prove their environmental commitment. RFID adhesive tags support this agenda by enabling smarter inventory management and reducing excess production.

Main contributions:

- Lower waste: real-time visibility prevents overstocking and expired products, especially in food and healthcare supply chains.

- Circular economy: RFID tracks returnable transport items (RTIs) like pallets and crates, extending their lifecycle and reducing single-use packaging.

- Material innovation: suppliers are developing recyclable and biodegradable RFID labels, decreasing the plastic footprint of billions of tags produced annually.

How RFID Adhesive Tags Work: From Chip to Data

Behind every RFID adhesive tag lies a simple but powerful system that connects the physical and digital worlds.

Core components:

- Tag: a microchip attached to an antenna, embedded in an adhesive layer.

- Reader: emits radio waves that power the tag and capture its data.

- Antenna: bridges communication between tag and reader, enabling multiple items to be identified at once.

How it works:

When a reader sends out a signal, nearby tags respond with their unique Electronic Product Code (EPC). This code can store product details such as batch, expiry, or serial number. Because passive RFID tags don’t require batteries, they last longer and are cost-effective for large-scale use.

Key advantages:

- No line-of-sight required, unlike barcodes.

- Hundreds of items can be read in seconds.

- Data integrates automatically into ERP, WMS, or MES systems, creating real-time visibility across operations.

Conclusion

RFID adhesive tags are no longer an emerging tool — they are a proven technology that delivers real-time accuracy, faster operations, and stronger control across industries. From retail to logistics, from food safety to manufacturing, RFID creates efficiency, reduces waste, and supports sustainability.

For leaders, the message is clear: adopting RFID adhesive tags is not just about tracking items, but about transforming operations into ecosystems of precision and control. The return comes in better data, fewer losses, and a more resilient business prepared for the future.

Is your company ready to take control of its inventory and assets with RFID adhesive tags?

Contact the experts at CPCON and unlock the power of RFID for total control and efficiency.

FAQ

1) What are the main benefits of RFID adhesive tags compared to barcodes?

RFID adhesive tags don’t require line-of-sight, read multiple items at once, and provide real-time accuracy above 90%, while barcodes are slower and prone to human error.

2) How do RFID adhesive tags improve retail operations?

They increase stock accuracy, prevent stockouts, and support omnichannel services like click-and-collect or ship-from-store, enhancing both efficiency and customer experience.

3) Can RFID adhesive tags be used in food safety and traceability?

Yes. They store batch and expiry information, enabling faster recalls, better rotation, and compliance with regulations such as FSMA 204.

4) Are RFID adhesive tags cost-effective for logistics and manufacturing?

Although there is an initial investment, RFID adhesive tags reduce labor, shrinkage, and errors, with ROI proven in logistics, automotive, and industrial supply chains.

5) How do RFID adhesive tags integrate with ERP and warehouse systems?

They connect via readers and middleware that send Electronic Product Code (EPC) data to ERP, WMS, or MES systems, updating inventories and workflows in real time.

Get to Know CPCON Group: A global expert in asset management and inventory solutions

CPCON Group is a global leader in asset management, fixed asset control, and RFID technology. With over 25 years of experience, we have supported major companies such as Nestlé, Pfizer, Scania, BASF, Coca-Cola Andina, Vale, Vivo, Petrobras, and Caixa in high-complexity projects.

Curious about our global footprint? We are present in:

- North America: Toronto, New York, Miami, Minneapolis, Seattle, Dallas

- Latin America: São Paulo, Buenos Aires, Lima, Bogotá, Mexico City

- Europe: Lisbon, Porto, London, Birmingham, Milan, Rome, Turin, Madrid, Bilbao

- Middle East: Dubai, Saudi Arabi

- Caribbean: Tortola, Grand Cayman

Follow our LinkedIn Showcase Page and stay updated with strategic content on asset control, inventory management, and RFID innovation across industries.

RFID adhesive tags give items a digital identity, enabling real-time tracking and 95%+ inventory accuracy. They transform retail, logistics, food safety, and manufacturing by reducing errors, waste, and costs. The technology integrates with ERP and WMS, automating processes and supporting compliance. With RFID adhesive tags, companies gain efficiency, sustainability, and total control over operations.