What if every product you bought came with a digital history you could check with your phone — showing where it was made, what it’s made of, and how to recycle it?

That’s exactly what the Digital Product Passport (DPP) sets out to do. Backed by new European regulations, the DPP will soon become mandatory for a wide range of goods. Its mission: bring full transparency to global supply chains and push companies to prove — not just promise — their sustainability efforts.

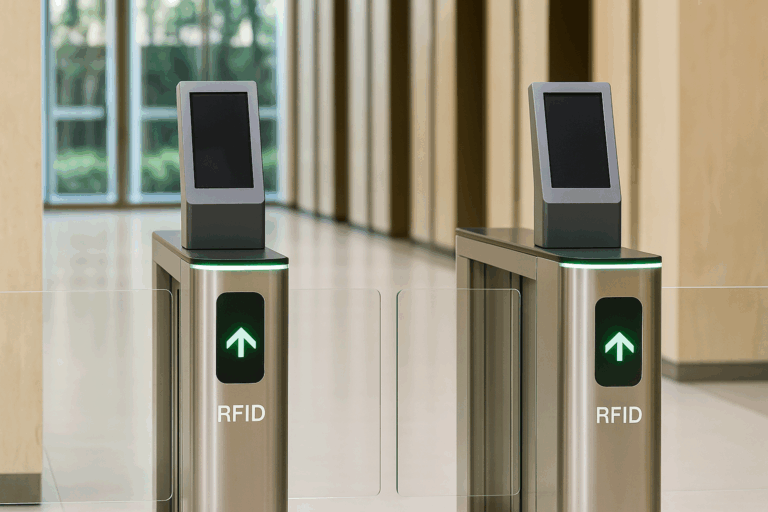

But how does this work in practice? That’s where RFID chips come in. These small devices make it possible to connect physical products to their digital identities in real time, making information accessible at every step — from production to disposal.

In this article, you’ll learn:

- What the Digital Product Passport really is

- Why RFID technology is key to making it work

- How this change affects businesses — including exporters to the EU

- And why early adoption can turn compliance into a competitive edge

Let’s explore how this powerful combination is changing the rules of supply chain transparency — and how your company can stay ahead.

Table of Contents

ToggleWhat is the Digital Product Passport (DPP) and why it matters in global trade

The Digital Product Passport, or DPP, is like a digital ID that travels with every product. It holds key information such as where the product was made, what materials were used, how much energy it consumed, and what to do with it when it reaches the end of its life.

In other words, it answers the questions that many consumers and regulators are now asking:

Where did this come from? What’s it made of? And how can we dispose of it responsibly?

This new model is not optional. It’s part of a regulation approved by the European Union called the Ecodesign for Sustainable Products Regulation (ESPR). The DPP will be mandatory for many products sold in the EU, starting with high-impact sectors such as batteries, textiles, and electronics.

But this isn’t just a European matter. Any company that wants to do business in the European market, including those based in Latin America, Asia, or North America, will need to comply. That includes manufacturers, distributors, and retailers that export to the EU.

For businesses, this means a shift in mindset. Transparency is no longer a nice-to-have. It is a legal and competitive requirement.

For consumers, this means real access to data they can trust. And for the planet, it means less waste, smarter choices, and a more circular economy.

Up next, let’s look at how RFID technology makes this digital passport possible in the real world.

Inside the EU Regulation: deadlines, impacted sectors, and what companies must know

The European Union is leading the shift toward more transparent and sustainable supply chains, and the Digital Product Passport is at the center of this transformation.

In 2024, the EU approved the Ecodesign for Sustainable Products Regulation (ESPR), a framework that requires companies to provide verified data about the environmental impact of their products. The DPP is the tool that makes this possible.

This change doesn’t just affect European manufacturers. It applies to any company that wants to sell into the EU, including exporters from Brazil and Latin America in sectors such as fashion, electronics, and consumer goods.

The regulation is being implemented in stages, with some key deadlines already confirmed:

- Batteries used in electric vehicles, industrial equipment, and e-bikes will require a digital passport starting February 2027. These passports must include carbon footprint data, material composition, and end-of-life instructions. (Arianee, Climatiq)

- The textile sector is expected to follow by 2030, with the first delegated acts planned for 2026, giving the industry time to prepare. (Intereconomics, Textile World)

- Other high-impact sectors already being prioritized include furniture, electronics, construction materials, and chemicals.

To make the DPP work globally, the EU is also investing in technical standards. These are being developed by CEN and CENELEC, two major European standardization bodies. The goal is to finalize harmonized formats by the end of 2025, ensuring that product data can be easily shared across different countries and systems. (WIOT Group)

What does this mean for your business? Companies that act early will avoid last-minute pressure and position themselves as reliable suppliers in global markets. Those that wait risk facing fines, loss of market access, and rising compliance costs.

Up next, let’s explore how RFID chips make this regulation work in practice — turning physical products into traceable digital assets.

How RFID technology connects the physical product to its digital passport

To make the Digital Product Passport work in real life, we need more than just data in the cloud. We need a way to connect each physical product to its digital identity — instantly and accurately. That’s where RFID technology comes in.

RFID stands for Radio-Frequency Identification. It uses a small chip and antenna to store and transmit data wirelessly. These chips can be embedded in labels, packaging, or even sewn into the product itself.

When scanned, the RFID chip instantly reveals the digital passport linked to that specific item. It acts as a bridge between the physical and digital worlds.

Here’s how RFID and the DPP work together to create a smarter, more transparent supply chain:

- Unique product ID: Each RFID chip holds a unique code that matches the product’s passport. No two items are the same.

- Real-time traceability: Products can be tracked from manufacturing to store shelf to end-of-life, giving companies full control over their inventory and logistics.

- Data accuracy: Unlike manual barcodes, RFID works automatically and reduces the risk of human error.

- Instant access for consumers: With the right infrastructure, smartphones or RFID readers can scan a product and pull up the full passport, helping consumers make informed decisions.

The European Commission has confirmed that RFID is one of the primary candidates for the data carrier of the Digital Product Passport, alongside QR codes and NFC. However, RFID offers key advantages, especially for industries that rely on speed, automation, and bulk reading. (Intereconomics)

In many pilot projects across Europe, companies are already combining RFID with the DPP to improve tracking, avoid counterfeit goods, and support recycling processes. The combination of both technologies is becoming a best practice for circular economy goals.

In the next section, we’ll explore how this impacts your business — not just to comply with the rules, but to gain real strategic benefits.

Strategic advantages of adopting DPP and RFID for your business

Many companies see the Digital Product Passport as a regulatory burden. But those who look deeper will find a real opportunity to gain efficiency, improve brand trust, and lead in a competitive market.

By adopting RFID technology alongside the DPP, your business can unlock several key benefits:

1. Smarter supply chain operations

RFID allows real-time tracking of items through production, warehousing, and distribution. This leads to:

- Lower inventory costs

- Fewer lost or misplaced products

- Faster response to demand and logistics issues

2. Stronger consumer trust

Today’s buyers want to know more. They care about where a product came from, how it was made, and what to do with it after use. DPP and RFID make this data visible and credible.

Companies that provide this level of transparency tend to gain greater customer loyalty and stand out in a crowded market.

3. Protection against counterfeits

With RFID and the DPP, each product gets a verified identity. This helps prevent fraud, especially in high-value or regulated sectors like electronics, luxury goods, and pharmaceuticals.

4. Easier compliance and ESG reporting

When product data is accurate and automated, generating compliance documents becomes faster and more reliable. This helps your company meet:

- EU sustainability regulations

- Corporate ESG targets

- Customer audits and traceability requirement

Research published in 2025 by Climate Strategy & Partners estimates that DPP adoption could reduce compliance costs by €200 million annually for electronics companies, simply by avoiding manual packaging changes. (Climatiq Report)

The message is clear: adopting DPP and RFID isn’t just about staying legal. It’s about building a smarter, cleaner, and more trustworthy business.

Next, let’s explore the practical side — the common challenges companies face and how to overcome them.

Overcoming the challenges: costs, data management, and standardization

While the Digital Product Passport and RFID bring clear benefits, adopting them across a business is not always simple. Companies of all sizes face practical challenges — but they can be solved with the right strategy and partners.

1. Cost of implementation

Deploying RFID and building digital product passports requires an initial investment. This includes:

- RFID tags and readers

- Software to manage product data

- Integration with existing ERP or inventory systems

However, studies have shown that these investments often pay for themselves within 12 to 18 months, thanks to efficiency gains and fewer losses. In sectors with high product turnover, like retail and electronics, the return on investment can be even faster. (RFID Journal ROI Study)

2. Managing complex data

To build a complete digital passport, companies need to collect and organize data from different parts of the supply chain: materials, production, logistics, and environmental impact.

This requires strong internal coordination and the right digital tools. Many businesses are turning to Product Information Management (PIM) systems and cloud platforms to centralize and automate the process.

European standardization bodies are working to simplify this. In 2025, CEN and CENELEC launched a roadmap to define the technical architecture for DPP interoperability, with expected finalization by December 2025. (WIOT Group)

3. Lack of global standards

Without shared rules, each company or country might create its own version of the DPP. That’s a risk for global supply chains.

The EU is leading efforts to define harmonized formats, including what data must be included, how it should be structured, and how it can be accessed securely. These standards are essential for interoperability and will become mandatory for affected sectors starting in 2027. (Intereconomics)

4. Need for training and change management

Technology alone doesn’t drive change. Teams must be trained to use RFID equipment, manage new processes, and understand how to handle compliance requirements.

The most successful companies in this space treat the transition as a digital transformation, not just a tech upgrade. They involve supply chain managers, IT teams, sustainability leaders, and external partners in the process.

With the right support and preparation, the barriers to adoption become stepping stones. And the sooner a company starts, the more room it has to learn and lead.

Coming up next: real-world examples of how DPP and RFID are already being used across different industries.

Emerging technologies and 2025 updates: blockchain, IoT and sustainable RFID tags

As the Digital Product Passport gains traction, new technologies are being integrated to make the system more secure, scalable and environmentally friendly. In 2025, several developments are shaping how companies prepare for the future of traceability.

Blockchain for data security and integrity

Blockchain is being explored as a complementary layer to the DPP. It offers a decentralized and tamper-proof way to store and verify product information. When combined with RFID, it helps guarantee that the data accessed through a product’s digital passport is authentic and hasn’t been altered.

This is especially valuable for high-risk sectors like luxury goods, medical devices and supply chains with many intermediaries. Brands like LVMH and Mercedes-Benz have tested blockchain-backed passports for product authenticity and carbon footprint tracking. (Forbes Blockchain Supply Chain)

While blockchain is not yet a mandatory requirement under EU regulation, its use is growing fast as companies seek to strengthen the trust in their ESG reporting.

IoT and smart monitoring in real time

The integration of RFID with Internet of Things (IoT) platforms allows businesses to monitor products in motion — in real time. Sensors connected to RFID readers can detect location, temperature, humidity or exposure to sunlight during shipping and storage.

This helps companies:

- Prevent product damage and recalls

- Improve route planning and logistics

- Ensure regulatory compliance for sensitive goods

In 2025, several logistics providers in Europe and Asia began integrating DPPs with IoT to create full visibility from factory to end customer. (GS1 IoT in Supply Chains)

Eco-friendly RFID tags for circularity

A rising concern in 2025 is the environmental footprint of the RFID tags themselves. Traditional tags often contain plastic and metal that are difficult to recycle.

To address this, companies are developing biodegradable and recyclable RFID tags made from paper, organic ink and other eco-friendly materials. Tags embedded in fabric or dissolvable adhesives are also gaining popularity in apparel and packaging.

Startups like PragmatIC and PulpaTronics are leading the way with sustainable RFID solutions for large-scale product identification. (Packaging Europe: RFID Innovations)

As more brands look to adopt DPPs, the sustainability of every component — including the tag — becomes part of the bigger conversation.

These innovations reinforce the idea that the DPP is not just a regulatory obligation. It is part of a larger digital transformation in how we manage products, track materials, and reduce waste across industries.

Next, we’ll look at how the CPCON Group helps companies make this shift with confidence, control and efficiency.

How CPCON helps your company adopt RFID and the DPP

Implementing RFID and preparing for the Digital Product Passport doesn’t need to be complex. CPCON offers a complete solution to make this transition simple, secure and scalable.

We support your company with:

- RFID infrastructure: Tags, readers and antennas customized to your product and environment

- System integration: Connection with your ERP, inventory and product lifecycle platforms

- Digital passport setup: Data mapping, structuring and formatting based on EU standards

- Operational support: From pilot projects to full implementation and team training

With CPCON, your company gains visibility, control and compliance — all while building a smarter and more sustainable supply chain.

Ready to lead in transparency and compliance?

Talk to our team and discover how CPCON can simplify your RFID and Digital Product Passport implementation.

Driving sustainability and competitiveness through traceability

Traceability is no longer optional. It’s becoming a core part of how companies operate, compete and grow in a connected global market.

The Digital Product Passport and RFID technology are not just regulatory tools. They are powerful enablers of efficiency, transparency and trust. Together, they allow businesses to:

- Prove the origin and impact of their products

- Comply with international sustainability standards

- Optimize logistics and reduce operational waste

- Engage consumers through information and integrity

More than just staying compliant, companies that invest early gain a strategic edge. They lead the shift toward circularity, reduce their exposure to risk and build stronger brands.

With the right support, the path to adoption becomes clear. That’s why CPCON is here — to help your business take control of its supply chain, data and future.

Want to learn more about supply chain innovation, RFID, and sustainability strategies?

Visit our blog and explore the latest insights to keep your business one step ahead.

FAQ

What is the Digital Product Passport and what information does it include?

The DPP is a digital record that stores data about a product’s origin, materials, carbon footprint and recycling instructions. It allows for full transparency across the supply chain.

When will the Digital Product Passport become mandatory in the EU?

Implementation starts with batteries in 2027, followed by sectors like textiles, electronics and furniture over the next few years. Full rollout depends on delegated acts under the EU’s Ecodesign Regulation.

How does RFID technology improve traceability?

RFID enables real-time tracking of individual products by linking each one to its digital passport. It replaces manual processes with automatic, accurate data capture.

What are the benefits of combining DPP and RFID for companies?

Companies gain inventory control, reduce operational waste, prevent counterfeiting and simplify compliance. They also build consumer trust through greater transparency.

The Digital Product Passport (DPP) and RFID technology work together to bring transparency, traceability and compliance to global supply chains. Mandated by EU regulation, the DPP will soon be required in key sectors like batteries, textiles and electronics. RFID enables real-time data capture and connects physical products to their digital profiles, helping companies reduce waste, prove sustainability and meet international standards. Businesses that act early can turn regulatory pressure into operational efficiency and market leadership.

Discover CPCON Group: Global expertise in asset control and inventory solutions

CPCON Group is a global leader in asset management, fixed asset control, and RFID technology — trusted by companies like Nestlé, Pfizer, Scania, BASF, Coca-Cola Andina, Vale, Vivo, Petrobras, and Caixa.

With over 25 years of experience, we support complex operations across industries by delivering precision, innovation, and total visibility over assets. Our offices span North America, Latin America, Europe, the Middle East, and the Caribbean, including cities like New York, São Paulo, Lisbon, London, Dubai, and Grand Cayman.

Want to explore our global presence? We’re active in:

- North America: Toronto, New York, Miami, Minneapolis, Seattle, Dallas

- Latin America: São Paulo, Buenos Aires, Lima, Bogota, Mexico City

- Europe: Lisbon, Porto, London, Birmingham, Milan, Rome, Turin, Madrid, Bilbao

- Middle East: Dubai, Saudi Arabia

- Caribbean: Tortola, Grand Cayman

Follow our LinkedIn Showcase Page to dive deeper into our insights, trends, and global solutions for asset control, inventory management, and RFID innovation.