In the cleaning products industrial sector, where production is intense and demand is fast-paced, maintaining control over inventory and deliveries is a strategic challenge. Without real-time visibility, small errors can quickly scale into major losses — from product shrinkage and inventory discrepancies to misplacements and delayed distribution.

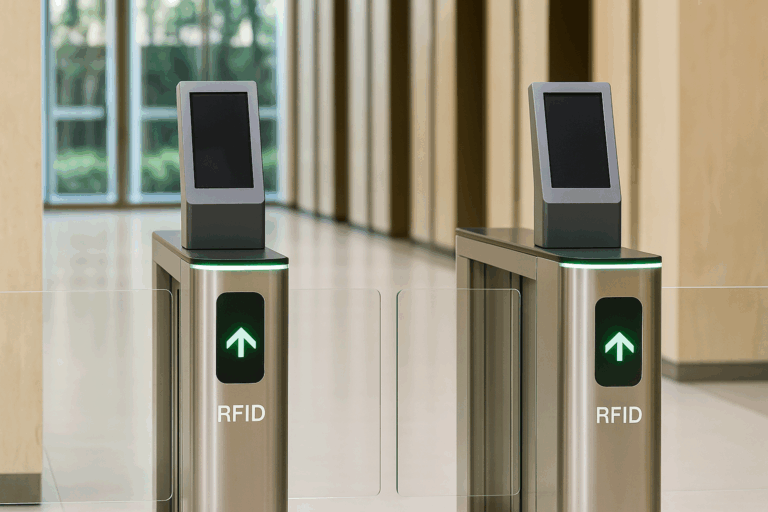

This scenario is especially critical in operations with high turnover and tight schedules. Without the right technology, counting is slow, error-prone, and vulnerable to disorganization. Products disappear, deadlines are missed, and losses mount. With RFID, each box is automatically identified from the production line to the retailer — enabling total traceability and no room for error. This article explores how RFID works in practice, the key benefits it brings to manufacturers, and how CPCON helps companies achieve full control, efficiency, and visibility across their entire operation.

Table of Contents

ToggleThe Main Bottlenecks in Cleaning Products Industrial Production and Distribution

The cleaning products industrial supply chain requires a fast pace, strict control, and immediate responsiveness. Yet many companies in the sector still rely on manual processes or partially digitized systems, which create a range of bottlenecks that compromise operational efficiency.

The most common issues include counting errors, product losses, inventory discrepancies, misplacements, and delivery delays. Without reliable traceability, it’s difficult to locate specific batches, rework increases, and the company’s credibility with distributors and retailers is weakened. Additionally, without accurate data, making real-time strategic decisions — such as rescheduling production, redirecting shipments, or responding to audits — becomes nearly impossible.

In a sector where timelines are tight and error tolerance is minimal, any failure in inventory or shipping control can result in significant financial loss. Overcoming these bottlenecks is not just about improving operations — it’s a critical step toward staying competitive and sustainable.

Operational Benefits of RFID for Cleaning Products Manufacturers

Imagine a cleaning products industrial facility producing thousands of units each day. At every stage — from bottling to shipping — control is done manually or through barcode scans that must be read one by one. Time is lost, mistakes build up, and the team struggles to meet retail demands without constant rework.

RFID technology completely transformed this operation. Each box became uniquely identified through a chip, enabling simultaneous, automated readings of large volumes. The result? A process that once took hours now takes minutes — with high precision and automated traceability, leaving no room for errors. The company gained full end-to-end visibility: it knew exactly how many boxes were produced, where they were sent, and when they arrived at the retailer.

Key benefits included:

- Reduced losses and misplacements: real-time tracking made it possible to quickly identify the location of any product in case of delivery issues or stock disruptions.

- Fewer operational errors: mistakes during counting and picking were nearly eliminated thanks to automated RFID readings.

- Increased team productivity: automation freed up staff for more strategic roles, reducing overload and boosting efficiency.

- Better control over schedules and deliveries: accurate data helped anticipate logistics problems and respond quickly to retail requirements.

- Audit readiness: with an asset and inventory management system integrated into the ERP, reports were always audit-ready without manual adjustments.

This level of transformation is only possible when RFID is applied with technical precision — from process mapping to system integration. Successful implementations rely on specialized teams that can adapt the RFID solution to the industrial environment, configure readers correctly, and ensure that data flows reliably and in real time.

Implementing RFID isn’t just about adopting a new tool. It’s about restructuring operational control in the cleaning products industrial sector with intelligence and long-term strategy.

Integrating RFID Technology with ERPs and Legacy Systems

For RFID technology to deliver tangible results, it must integrate with the company’s existing digital ecosystem — especially enterprise resource planning (ERP) systems and inventory management platforms. In the cleaning products industrial sector, this integration is the key to real-time decision-making and streamlined information flow.

Rather than creating a separate system, RFID acts as an intelligent sensor embedded within the operation. Data captured by the readers — such as product location, quantity, movement, and status — is automatically transmitted to the company’s ERP. This enables all departments, including production, logistics, quality, and finance, to access synchronized and reliable information instantly.

A well-executed integration also eliminates rework, minimizes data inconsistencies, and speeds up processes like billing, invoicing, expiration tracking, and cycle counting. Advanced solutions can even trigger automatic alerts in cases of discrepancies, losses, or stockouts — increasing control with minimal human intervention.

Projects that succeed in this area often involve partners who understand both operational workflows and the technical demands of systems like SAP, TOTVS, Oracle, and others. This multidisciplinary perspective ensures that RFID is not just an isolated innovation, but a foundational element of efficiency in the cleaning products industrial operation.

How CPCON Supports the Cleaning Products Industrial Sector with End-to-End RFID

In the cleaning products industrial sector, adopting RFID is not just a technological decision — it’s a strategic one. That’s where CPCON stands out: with proven experience in industrial projects, the company offers an end-to-end approach that connects every stage of the operation, from production to distribution.

Before implementation, a complete diagnostic of the production and logistics environment is conducted to identify risks, bottlenecks, and opportunities. From there, a customized RFID system is designed, including the optimal selection of antennas, readers, tag placement, and label types. Every detail is engineered to ensure accurate readings even in challenging environments, such as areas with chemicals, steam, or high humidity.

Beyond the technology itself, CPCON ensures that the RFID system integrates seamlessly with the ERPs and software already used by the company. The integration is carefully planned to preserve data consistency and enhance the value of information across the entire supply chain — from inventory control to executive-level analysis.

Another key differentiator is ongoing support. After activation, CPCON remains alongside the client’s team, providing training, performance monitoring, and fine-tuning as the operation evolves. This ongoing partnership is what ensures not just immediate efficiency, but long-term sustainability.

In a sector defined by high volumes, tight deadlines, and increasing demands for traceability, implementing RFID with intelligence allows companies to gain real control, reduce losses, and strengthen their market position. With CPCON as a partner, this transformation becomes faster, safer, and more profitable.

Conclusion

In the cleaning products industrial sector, every logistical error comes at a cost. Lack of visibility, rework, and product losses are not just operational issues — they signal processes in urgent need of transformation. RFID technology offers a direct solution by enabling traceability, control, and agility through automated, reliable data.

More than just a tool, RFID becomes a pillar of industrial efficiency. When properly implemented and integrated with business systems, it enables faster decisions, reduces waste, and prepares operations for audits and scalable growth. With CPCON, this transformation happens in a structured, secure, and strategically impactful way.

Ready to gain full visibility and control over your cleaning products industrial operation?

FAQ

Why is RFID ideal for the cleaning products industrial sector?

RFID provides automated control and real-time traceability, which are critical in environments with high item turnover and tight deadlines.

How does RFID improve inventory management in cleaning products manufacturing?

It enables bulk reading without line of sight, drastically reducing errors and speeding up counting, picking, and shipping processes.

Can RFID integrate with the ERP systems we already use?

Yes. RFID systems can be integrated with platforms like SAP, TOTVS, Oracle, and others, ensuring data consistency across your digital infrastructure.

Is RFID reliable in environments with chemicals or high humidity?

Absolutely. With the right hardware configuration and tag selection, RFID performs accurately even in harsh industrial conditions.

How long does it take to implement an RFID project?

Timelines vary by complexity, but with a detailed technical diagnosis and specialized team, companies often see results within weeks.

Does RFID help with audits and compliance?

Yes. All product movements are automatically recorded, generating audit-ready reports and supporting strong internal controls.

How does CPCON ensure a successful RFID implementation?

CPCON delivers diagnostics, custom project design, ERP integration, equipment supply, staff training, and continuous support — ensuring long-term results for cleaning products industrial operations.