An RFID Inventory System is a technology that automates item reading, eliminating manual counts and reducing operational losses. With smart tags and radio-frequency sensors, you can track every movement in real time — from receiving to storage, from shipping to audit.

If your company still relies on spreadsheets or manual inventories, the risk of inconsistency and rework is high. An RFID inventory system delivers accuracy, agility, and complete control, even in complex operations with thousands of assets.

In this article, you will learn:

- How an RFID system works for inventory control

- The practical benefits of the technology in daily operations

- Where RFID applies within the operation (receiving, storage, shipping, audit)

- What results leading companies are achieving with RFID

- Why this solution is ideal for businesses seeking to scale with efficiency and full control

Table of Contents

ToggleWhat an RFID System Is — and How It Works in Inventory Control

An RFID system (Radio Frequency Identification) is a technology that identifies and tracks items automatically, without line-of-sight or manual scanning. Each product or asset receives a tag with an RFID chip that stores information and communicates with sensors through radio waves.

These sensors, called RFID readers, capture tag data in real time — even when items are stacked, packaged, or moving. This eliminates manual entries, reduces errors, and guarantees full visibility of operations.

In practice, an RFID system works with three key elements:

- RFID tags: Applied to cartons, pallets, parts, or equipment. They can be attached by adhesive, stitching, or mounting.

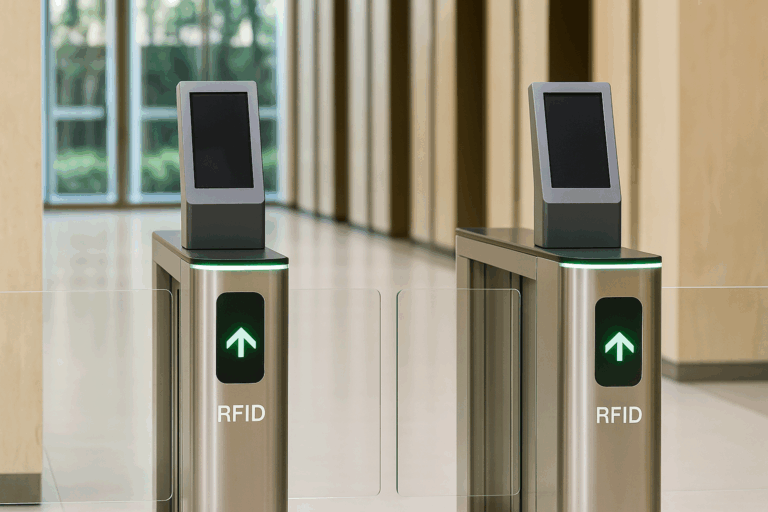

- RFID readers and antennas: Installed at strategic points — docks, aisles, portals, or shelves — to capture tag signals.

- Management software: Receives real-time data and organizes it into dashboards, reports, and alerts.

With this structure, the entire inventory flow can be automated. Reads are fast, silent, and can reach up to 99% accuracy.

Practical Benefits of RFID: Control, Agility, and Precision

Implementing an RFID system for inventory control is not just modernization — it is a direct way to increase operational efficiency and reduce losses.

In practice, RFID delivers immediate and measurable benefits:

Real-time control

- Every inbound, outbound, or transfer movement is automatically recorded.

- You know exactly where each item is, at which stage of the process, and in which physical location.

Automated inventory

- Up to 90% reduction in inventory time with simultaneous reading of hundreds of items.

- Eliminates manual counts or barcode scanning.

Loss and deviation reduction

- Real-time alerts for discrepancies, unauthorized movements, or missing items.

- Helps trace logistics failures and prevent internal or external theft.

Integration with management systems

- RFID connects to ERP and WMS, automatically updating records.

- Data stays synchronized between physical and book inventory.

Strategic stock visibility

- Dashboards and management reports with performance indicators.

- Supports decision-making based on reliable, updated data.

These gains are noticeable from small retail chains to large distribution centers.

RFID Applications in Inventory Management: Efficiency Across Industries

CPCON’s RFID system is a versatile technological solution that adapts to different operational contexts and industries. By automating identification and tracking, it enhances control and efficiency — from industrial environments to retail and healthcare operations.

Here’s how RFID applies in practice across sectors:

Industry

- Real-time tracking of parts and products from production to shipping

- Fixed-asset and tool management with usage and location control

- Preventive maintenance optimization with automated alerts

- Access control to restricted areas, increasing operational safety

Logistics

- Real-time monitoring of cargo and goods in transit

- Automated inbound and outbound at warehouses without spreadsheets or manual checks

- Loss, exception, and damage reduction with alerts for unauthorized movements

- Faster picking and packing with higher shipping accuracy

Retail

- Accurate real-time stock visibility across stores, distribution centers, and e-commerce

- Loss prevention for theft or out-of-stocks with continuous inventory control

- Improved customer experience with smart shelves, fast replenishment, and personalized service

Healthcare

- Tracking medications and sensitive supplies with temperature and expiry control

- Hospital equipment management with real-time location and usage history

- Prevention of medication errors, ensuring greater patient safety

- Automated control of surgical materials and PPEs in critical environments

Other sectors

- Events & conventions: real-time access control and people flow management

- Livestock & agribusiness: animal tracking and supply control

- Asset management: automated control of movable assets such as computers, furniture, and instruments

RFID Tags: What They Are, Best Options, and Formats

What are RFID tags?

RFID tags, also known as RFID labels, are small devices made of a microchip and an antenna. They work by transmitting and receiving radio signals, allowing stored data to be read at a distance — without physical or visual contact with the item.

This wireless operation enables hundreds of items to be identified automatically and simultaneously — even when moving, stacked, or inside packaging.

Tip: Tag and label refer to the same device, with different uses:

- RFID tag is the technical term, most common in industry.

- RFID label is the popular term, often used in retail and logistics.

These tags can contain various information, such as:

- Product code and description

- Manufacturing and expiration dates

- Serial and lot numbers

- Current location

- Item condition (new, used, damaged)

Most Common RFID Tag Types for Inventory Control

Choosing the right RFID tag depends on the product type, environment, and the required level of traceability. Here are the main types:

UHF (Ultra High Frequency) tags

- Frequency: 860–960 MHz

- Read range: up to 10 meters

- Ideal for:

- Large-area inventories

- Pallet and cargo tracking

- Environments with many physical obstacles

HF (High Frequency) tags

- Frequency: 13.56 MHz

- Read range: up to 1 meter

- Indicated for:

- High-value items

- Access control

- Fast, precise reads at fixed locations

LF (Low Frequency) tags

- Frequency: 125–134 kHz

- Read range: up to 10 cm

- Recommended for:

- Heavy industrial environments

- Metal assets

- Situations requiring durability and low cost

RFID Tag Formats

Beyond frequency, tag formats vary according to the application:

- Adhesive labels: applied directly to cartons, packages, and products

- Rigid (hard tags): resistant to impact, heat, or humidity

- Textile tags: sewn into clothes or uniforms, ideal for laundries

- On-metal tags: designed for metallic surfaces

- Sensor tags: monitor temperature, shock, or tampering

Why Choose RFID Tags for Your Inventory?

RFID tags are widely used in sectors such as retail, logistics, healthcare, industry, and distribution centers. Their main benefits include:

- Automatic, contactless reading

- Real-time tracking

- Loss and theft reduction

- Faster physical inventories

- Better control over expiration and item movement

With the right tag, your company gains efficiency, visibility, and security — without relying on manual processes prone to error.

RFID vs Barcode: Key Differences — Which One Fits Your Inventory?

The barcode is a traditional technology, used for decades in inventory control and logistics. While still useful in many cases, it has clear limitations compared to RFID — especially for companies handling high asset volumes, requiring precise traceability, or seeking large-scale automation.

Advantages of RFID over Barcodes

- Automated inventory: eliminates the need for item-by-item scanning

- Real-time accuracy and traceability: each product can be identified individually

- Lower risk of losses and theft: with continuous monitoring and alerts

- Better team productivity: no manual scanning required

- Operational scalability: ideal for companies expanding or with decentralized operations

And Where Does NFC Fit?

NFC (Near Field Communication) is a variation of RFID technology with very short read range, designed for more specific applications such as payment systems and individual access control. While highly secure, its use in inventory management is limited due to its short range.

Visual Comparison: RFID vs Barcode vs NFC

A radar chart can help visualize the main differences:

- Implementation cost: Barcode (low) | NFC (medium) | RFID (higher)

- Read range: RFID (long) | Barcode (short) | NFC (very short)

- Accuracy: High for all, with a slight edge for RFID and NFC

- Interference resistance: NFC (high) | RFID (medium) | Barcode (low)

- Data security: NFC (high) | RFID (medium) | Barcode (low)

Compatibility with Existing Systems

It’s important to highlight that CPCON’s RFID system is fully compatible with barcodes, allowing companies to integrate technologies gradually without losing current controls. This makes migration easier and reduces implementation risks.

In the Long Run, RFID Is the Strategic Choice

While barcodes may still serve smaller businesses or manual operations, RFID has proven to be the most effective technology for modern inventory control. Its gains in accuracy, automation, tracking, and scalability justify the investment — especially for operations that demand speed, reliability, and full visibility.

RFID Inventory Control System: the Next Step to Scale with Efficiency

More than just a trend, RFID represents a transformation in the way inventory is managed. And to make this shift securely, it is essential to rely on specialists.

CPCON Group combines advanced technology, hands-on experience, and tailored solutions to make your operation more efficient, secure, and scalable.

CPCON Solutions for RFID-Enabled Inventory Control

CPCON offers complete and customized solutions for companies looking to implement RFID strategically:

- Deployment of fixed or mobile RFID portals and readers

- Supply and customization of RFID tags

- Integration with ERP, WMS, and inventory systems

- Platforms with real-time dashboards

- Automated inventories with high accuracy

- Technical consulting and ongoing support

FAQ

What is an RFID Inventory System?

It is a technology that uses radio frequency to identify and track items automatically, without manual scanning or physical contact.

What are the main benefits of RFID over barcodes?

RFID enables mass reading, real-time tracking, and more durable tags. It reduces errors, losses, and rework while improving operational efficiency.

How do I choose the right RFID tag for my inventory?

The choice depends on product type, operating environment, and tracking needs. CPCON analyzes each operation to recommend the most effective model.

Can RFID integrate with my current ERP or WMS?

Yes. CPCON’s RFID solutions integrate seamlessly with systems such as SAP, Oracle, TOTVS, and many others.

What is the first step to implement RFID in my company?

The ideal starting point is a technical assessment. CPCON offers specialized consulting to map processes and define the best implementation approach.

Get to Know CPCON Group: A global expert in asset management and inventory solutions

CPCON Group is a global leader in asset management, fixed asset control, and RFID technology. With over 25 years of experience, we have supported major companies such as Nestlé, Pfizer, Scania, BASF, Coca-Cola Andina, Vale, Vivo, Petrobras, and Caixa in high-complexity projects.

Curious about our global footprint? We are present in:

- North America: Toronto, New York, Miami, Minneapolis, Seattle, Dallas

- Latin America: São Paulo, Buenos Aires, Lima, Bogotá, Mexico City

- Europe: Lisbon, Porto, London, Birmingham, Milan, Rome, Turin, Madrid, Bilbao

- Middle East: Dubai, Saudi Arabi

- Caribbean: Tortola, Grand Cayman

Follow our LinkedIn Showcase Page and stay updated with strategic content on asset control, inventory management, and RFID innovation across industries.

An RFID Inventory System automates item tracking with smart tags and radio-frequency sensors, eliminating manual counts and reducing losses. It offers real-time visibility, up to 99% accuracy, faster inventories, integration with ERP/WMS, and applications across retail, logistics, healthcare, and industry. Compared to barcodes, RFID enables mass reading, greater scalability, and higher security. CPCON provides global expertise with tailored RFID solutions, including tags, portals, dashboards, and consulting, helping companies scale operations with efficiency and control.