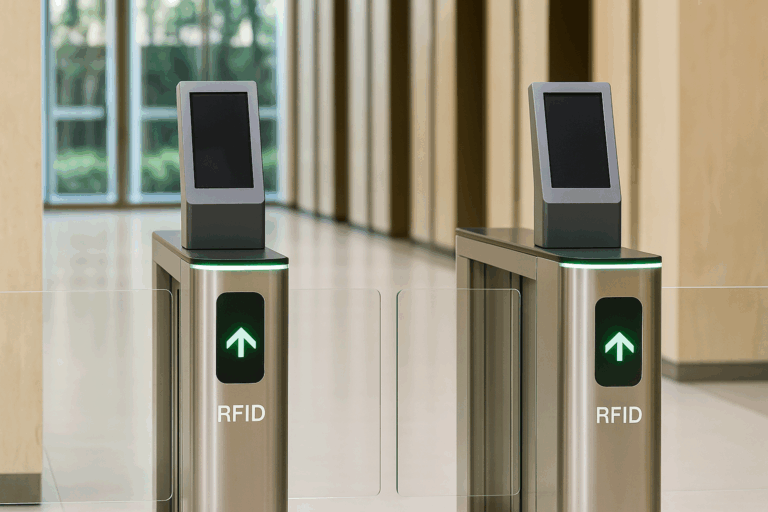

RFID for asset tracking and inventory management is the technology that allows companies to locate, identify, and control assets and inventory in real time with speed and accuracy. Unlike barcodes or spreadsheets, RFID uses radio frequency signals to scan hundreds of items at once—even if they are inside closed boxes or moving through the supply chain.

In practice, this means fewer human errors, inventory counts completed in minutes, and full visibility of where each asset is at any moment. For industries, retailers, hospitals, and distribution centers, adopting RFID for asset tracking and inventory management is not just about upgrading technology—it’s about turning operational control into a competitive advantage.

Table of Contents

ToggleWhy companies are turning to RFID for asset tracking and inventory management

Across industries, leaders are realizing that the real challenge is not buying or moving goods, but knowing exactly where each asset is at any given time. Manual counts, spreadsheets, and barcode scanning once worked, but they are too slow and prone to errors for today’s dynamic supply chains.

That’s why more organizations are adopting RFID for asset tracking and inventory management. The technology allows them to read hundreds of items simultaneously, track movements in real time, and eliminate blind spots in operations.

As Iasmim Godoy, Technology Director at CPCON, points out:

“RFID changes the way companies think about control. When managers have precise and up-to-date information, they stop firefighting and start leading with confidence. I’ve seen companies reduce inventory time from days to minutes while gaining full visibility over their assets. Once they experience that level of efficiency, there’s no going back.”

The real benefits of RFID for asset tracking and inventory management

When companies invest in RFID, the first difference they notice is speed. Inventory counts that once consumed hours—or even days—can now be completed in minutes. The second is accuracy. By eliminating manual errors, businesses gain reliable data that becomes the foundation for better decisions.

But the advantages don’t stop there. RFID for asset tracking and inventory management brings:

- Real-time visibility: knowing exactly where assets are and who moved them.

- Seamless integration: syncing with ERP, WMS, and BI systems for a single source of truth.

- Stronger compliance: automated logs that make audits simpler and more transparent.

- Operational security: fewer losses, less downtime, and safer handling of critical equipment.

According to Iasmim, these are not just technical wins, but strategic ones:

“Every company we’ve worked with reports the same pattern: fewer errors, faster processes, and more confident decisions. RFID doesn’t just optimize tasks—it empowers leaders to plan growth with precision. That’s why I say it’s more than technology; it’s a strategic tool for sustainable efficiency.”

Where RFID proves its value across industries

The benefits of RFID are not limited to one type of business. In manufacturing, it ensures that tools, pallets, and raw materials are always in the right place. In retail, it helps prevent losses and makes cycle counts part of the daily routine instead of a massive effort. Hospitals use it to keep track of critical equipment and medications, while construction companies rely on it to manage materials across different job sites.

As Iasmim explains, these examples all share one thing: visibility.

“Once you know exactly where your assets are, operations become more predictable. A retailer can avoid stockouts, a hospital can make sure a ventilator is available when needed, and a construction site can reduce delays caused by missing materials. That visibility turns into efficiency and, ultimately, into trust from clients and partners.”

RFID as a strategic decision, not just a tool

When companies first consider RFID, many see it as a technology upgrade. But as soon as the system is in place, leaders realize its impact goes far beyond faster inventories. It changes the way they manage risks, scale operations, and ensure compliance.

Iasmim highlights that the turning point usually happens when managers connect operational control with financial results:

“It’s common to hear leaders say they used to spend weeks reconciling physical and accounting records. With RFID, those numbers align almost instantly. That level of control creates confidence, not just for day-to-day operations but also for audits, reporting, and strategic planning.”

This is why RFID for asset tracking and inventory management is often described as a foundation for growth. By eliminating hidden costs—like misplaced equipment, duplicated purchases, or delayed deliveries—companies free up resources to invest in innovation and expansion.

As Iasmim sums up during the conversation, “you can’t scale chaos. RFID gives organizations the structure they need to grow without losing control.”

The future of RFID in asset tracking and inventory management

RFID is already transforming the way companies track assets, but its real potential is just beginning to unfold. As systems integrate with AI, IoT, and advanced analytics, the technology moves from simply showing where things are to predicting what will happen next.

Iasmim points out that the next step is automation on a much larger scale:

“We’re entering a stage where RFID tags don’t just identify an item—they feed data into intelligent systems that can forecast demand, optimize maintenance schedules, and trigger alerts before something goes wrong. That’s a major leap from operational control to strategic intelligence.”

For companies, this means more than efficiency. It means creating resilient supply chains, stronger compliance structures, and a foundation for ESG commitments. As sustainability becomes a priority, being able to prove traceability and transparency through RFID data will no longer be optional—it will be a requirement.

“Leaders who adopt RFID today are not just solving current problems,” she adds. “They are building the infrastructure that will keep their businesses competitive in the next decade.”

Conclusion

RFID for asset tracking and inventory management is no longer a “nice-to-have.” It has become a strategic pillar for companies that need speed, precision, and transparency. By turning inventory into a process measured in minutes instead of days, and by providing real-time visibility, RFID empowers leaders to make confident decisions and scale without losing control.

CPCON’s role in the future of RFID

At CPCON, we have been pioneers in applying RFID solutions for more than two decades. Our approach goes beyond implementing tags and readers—we design strategies that integrate RFID with ERP, WMS, BI, and compliance systems. With global expertise in asset management, internal control, and technology, we help organizations gain not only operational efficiency but also governance and long-term resilience.

For us, RFID is not just about controlling items. It is about empowering companies to innovate, expand, and consolidate with total confidence. That’s why CPCON is recognized as a global leader in asset tracking and inventory management.

Ready to take control of your assets and inventory with RFID?

Contact the experts at CPCON and discover how our global expertise can transform your operations with precision, visibility, and security.

FAQ

1. What is RFID for asset tracking and inventory management?

It is a technology that uses radio frequency signals to identify and monitor assets in real time, replacing manual counts and barcode scans.

2. How does RFID improve inventory accuracy?

By reading hundreds of items simultaneously, RFID reduces human error and ensures near-perfect accuracy in asset tracking.

3. Can RFID integrate with ERP and other corporate systems?

Yes. RFID integrates seamlessly with ERP, WMS, and BI platforms, centralizing information and supporting data-driven decisions.

4. Which industries benefit the most from RFID?

Manufacturing, retail, healthcare, logistics, and construction are among the sectors with the greatest gains from RFID adoption.

5. Why is RFID considered a strategic decision?

Because it reduces hidden costs, strengthens compliance, and builds the operational structure that companies need to grow safely and sustainably.

Get to Know CPCON Group: A global expert in asset management and inventory solutions

CPCON Group is a global leader in asset management, fixed asset control, and RFID technology. With over 25 years of experience, we have supported major companies such as Nestlé, Pfizer, Scania, BASF, Coca-Cola Andina, Vale, Vivo, Petrobras, and Caixa in high-complexity projects.

Curious about our global footprint? We are present in:

- North America: Toronto, New York, Miami, Minneapolis, Seattle, Dallas

- Latin America: São Paulo, Buenos Aires, Lima, Bogotá, Mexico City

- Europe: Lisbon, Porto, London, Birmingham, Milan, Rome, Turin, Madrid, Bilbao

- Middle East: Dubai, Saudi Arabi

- Caribbean: Tortola, Grand Cayman

Follow our LinkedIn Showcase Page and stay updated with strategic content on asset control, inventory management, and RFID innovation across industries.

RFID for asset tracking and inventory management replaces manual methods with real-time, automated control. It reduces errors, speeds up inventories, and integrates with ERP systems, benefiting industries from retail to healthcare. CPCON positions itself as a global leader in RFID strategies, combining technology and governance to drive sustainable growth.