In the refrigeration sector, time and precision mean everything. The movement of meat, the control of expiration dates, and the organization by batch must be executed with accuracy — even in extreme environments like cold rooms at -20 °C.

Manual counting under these conditions takes time, leads to mistakes, and puts workers’ health at risk. Smudged labels, lost data, and expired products are still common in many operations.

This is where RFID technology changes the game. With cold-resistant tags, smart antennas, and contactless readers, it’s possible to monitor stock in real time, automate routines, and ensure full traceability of expiration, quality, and batch.

In this article, you’ll understand why RFID is no longer just an option — it’s a strategic necessity for refrigeration facilities aiming for efficiency, safety, and cost reduction.

Table of Contents

ToggleWhy RFID is essential for refrigeration facilities operating in cold chains

RFID is essential for refrigeration facilities because it enables real-time product monitoring — even inside cold rooms — ensuring complete control over expiration dates, batch, and location.

This reduces losses, prevents human errors, and increases operational efficiency — all without exposing workers to long periods in freezing environments.

The daily routine of a refrigeration plant is intense. Tons of meat enter and leave storage areas every day.

Products must be stored at controlled temperatures while also complying with strict traceability standards.

When done manually, this process takes time, requires physical effort, creates data inconsistencies, and increases the risk of waste due to expiration or picking errors.

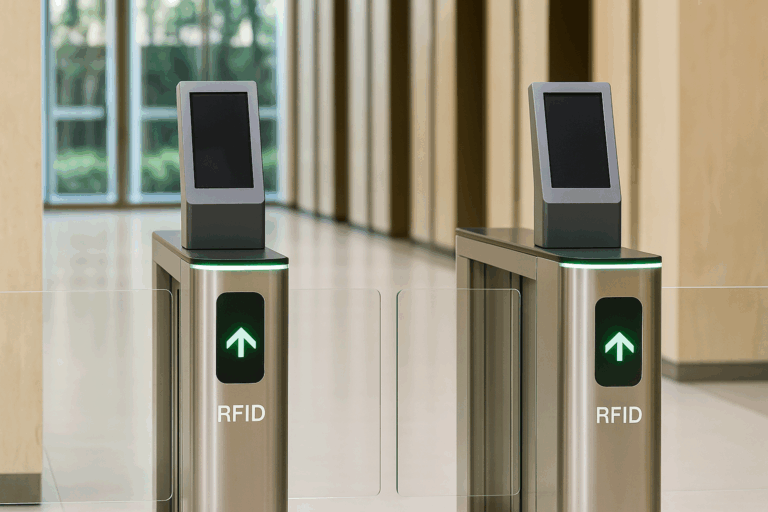

With RFID technology applied to cold chain logistics, this scenario changes completely. Each piece or box receives a cold- and moisture-resistant RFID tag.

When passing through a gate with an antenna installed, the data is automatically captured: product type, expiration date, batch, entry time, storage duration. All of this is sent directly to the system — no clipboards, no spreadsheets, no errors.

This level of automation allows the refrigeration facility to:

- Have real-time visibility of the exact location of every item

- React quickly to products nearing expiration

- Reduce inventory counting time from hours to minutes

- Greatly minimize staff exposure to subzero temperatures

- Generate automatic reports for audits and regulatory compliance

Traceability and safety: the major challenges in the meat industry

In the meat industry, traceability means knowing exactly where each product came from, where it’s been, and what condition it’s in.

Without it, the risks are high: lost batches, expired products, shipping mistakes, and even contamination.

This level of control is essential for two main reasons:

- Food safety: Meat is a perishable and sensitive product. A small error in temperature or labeling can affect its quality.

- Regulatory compliance: Authorities like MAPA and ANVISA require clear records of expiration, batch, and movement. For exporters, international standards also apply.

The problem is that many companies still rely on manual labels or spreadsheets. This slows down data collection and makes it impossible to act quickly during recalls, inspections, or logistic issues.

With RFID, traceability becomes automatic and much safer. Here’s what changes in practice:

- Each product receives a unique RFID code

- The tag is read without physical contact — it just needs to pass by an antenna

- Data is instantly sent to the system: batch, expiration, location, and storage time

- If something goes wrong, the full history can be retrieved in seconds

This technology replaces a slow and error-prone process with an intelligent and reliable system.

The result? More safety, less waste, and full control over the cold chain.

How RFID technology works in refrigerated environments

RFID works like an invisible ID that stays with each product. Instead of paper labels, it uses smart chips that can be read from a distance — even when there’s ice, fog, or stacked boxes in the way. And most importantly: no need to open anything or touch the products.

Inside a refrigeration facility — where it’s cold, damp, and space is often tight — this makes all the difference.

Here’s how it works:

- Each product receives an RFID tag — it can be attached directly to packaging or reusable plastic crates

- Antennas are installed in key spots, like cold room doors, hallways, and shipping areas

- As the meat moves through these zones, the system automatically reads the chip: what it is, which batch it belongs to, when it entered, and where it’s headed

- All the info goes instantly to a digital dashboard that shows the current inventory in real time — with zero human input

And here’s the best part: RFID keeps working even in the toughest conditions. These tags are designed to resist moisture, freezing, and constant movement. Nothing gets lost in the cold.

Unlike barcodes, RFID doesn’t need line-of-sight. That means it can read items even when they’re buried at the bottom of a stack or covered in frost — no need for flashlights or awkward scanner angles.

In large-scale operations, this kind of automation avoids line delays, picking errors, and unnecessary downtime. It’s like switching from a flip phone to a smartphone — you won’t go back.

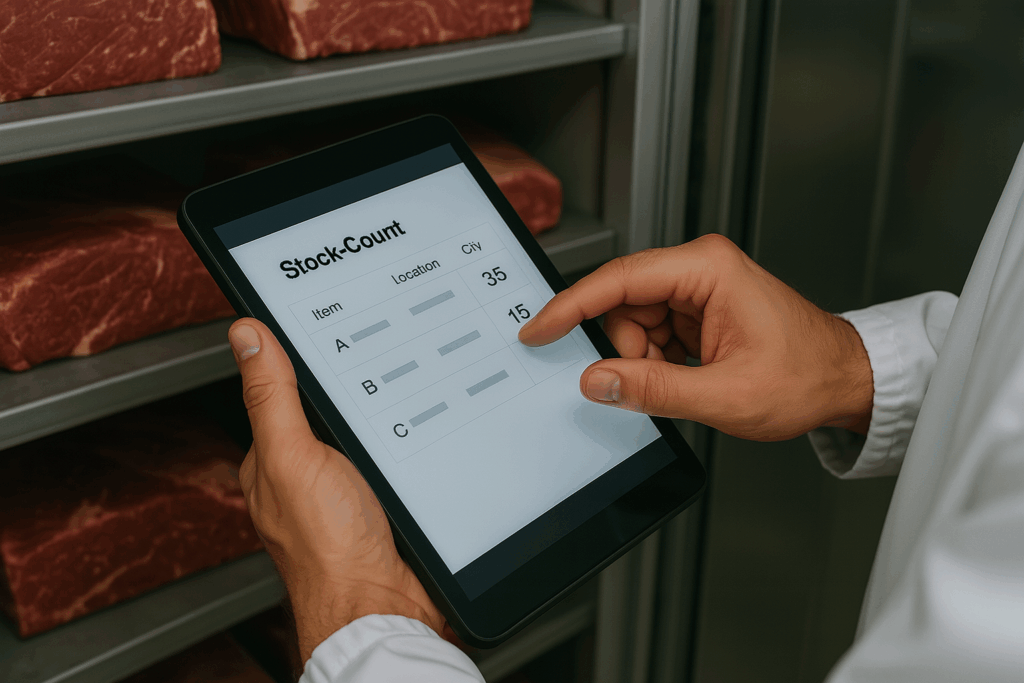

Full inventory, expiration, and batch control with RFID

Picture your inventory like a giant chessboard. Every piece — whether it’s a box of meat, a premium cut, or frozen offal — has a specific spot and value. Now imagine trying to play that game blindfolded.

That’s how many refrigeration plants still operate today: not knowing what’s about to expire, what just came in, or what’s missing in action.

RFID flips that scenario completely.

Instead of a dark and confusing stockroom, RFID turns your inventory into a live control panel where every item has a name, location, and time stamp. Nothing gets lost, nothing spoils unnoticed, and nothing is forgotten in some corner of a cold room.

Here’s what RFID handles automatically, without human error:

- Expiration by batch: if a group of items is close to expiration, the system alerts you before you even open the freezer door

- Smart organization: items are tracked by batch, origin, entry date, and destination — all visible in one click

- True FIFO rotation: the system suggests which products to ship out first based on age

- Alerts and notifications: is something expiring tomorrow? You’ll know today. A box is misplaced? You’ll be notified before it becomes a loss

This level of control isn’t a luxury — it’s the new standard. In a competitive market, knowing exactly what you have, where it is, and when it expires can mean the difference between profit and loss.

With RFID, refrigeration facilities leave behind the guesswork and enter the age of real-time, full control.

Ready to take full control of your cold storage inventory?

Talk to our experts and see how RFID can be tailored to your operation.

RFID versus barcodes in cold storage

If you’ve ever tried to scan a barcode inside a cold room, you know the struggle. The scanner fails, the label is wet, or worse — the employee has to take off their gloves, freeze their hands, and try again. Now imagine repeating that process with a thousand boxes.

That’s where RFID steps in — and steps ahead.

Think of barcodes as great for their time. But in refrigerated environments, they’ve become the landline of logistics. They still work, but they’re slow, limited, and not built for the demands of today’s operation.

RFID, on the other hand, is more like Wi-Fi for your stockroom. You don’t need to see the tag, touch the box, or even stop walking. It just reads everything, all at once.

Let’s make this even clearer:

| Feature | Barcode | RFID |

| Reading method | Manual, needs alignment | Automatic, remote reading |

| Cold and humid environments | Often fails | Designed to resist moisture and ice |

| Inventory speed | Slow, item by item | Fast, hundreds per second |

| Requires visual contact | Yes | No |

| Works with gloves and PPE | Difficult | Yes, contactless |

| Mass reading capability | No | Yes |

| Initial cost | Lower | Higher, but better ROI |

| Tag durability | Tears, fades easily | Long lifespan, even in freezing temps |

While barcodes require physical presence and patience, RFID runs invisibly in the background. It turns slow, repetitive tasks into a smooth, automated process.

And in the meat business, time is money — and control is everything.

Still unsure about making the switch? RFID isn’t just a better scanner. It’s a smarter way to run your inventory.

What RFID devices are ideal for cold storage environments?

Using RFID in refrigerated settings requires the right equipment. You can’t just pick any tag or reader — cold, moisture, and constant movement demand tough, smart technology.

Don’t worry. You don’t need to be an engineer to get the basics. Here’s a simple breakdown of what makes up a complete RFID system for cold storage operations:

1. Cold-resistant RFID tags

These are the stars of traceability. Each tag carries essential data about the product — batch, expiration, weight, and more. To survive in the cold, they must be:

- Waterproof and resistant to condensation

- Made with special adhesive that doesn’t peel off in freezing temps

- Equipped with durable chips that hold up under harsh conditions

- Available in formats that fit plastic boxes, flexible packaging, or pallets

There are also reusable versions, ideal for returnable crates, which increase your ROI over time.

2. Fixed RFID antennas

These are installed at key locations, like:

- Cold room doors

- Chilling tunnels

- Shipping and receiving areas

They act like invisible checkpoints: as products pass by, data is captured automatically. No stopping, no opening boxes, no manual input.

3. Handheld RFID readers

They look like barcode scanners, but they do much more. The operator simply points the device toward the stock and gets instant answers:

- What the product is

- How long it’s been stored

- Where it needs to go

These readers need to be waterproof, easy to handle with gloves, and have batteries that won’t die in cold conditions.

Common devices used in cold storage RFID systems

| Device Type | Main Function | Key Features |

| UHF RFID Tag | Tracks batch, expiration, and origin | Resistant to -25 °C, waterproof, long-range read |

| Fixed RFID Antenna | Reads products entering or exiting | Can be installed on doors, conveyors, or tunnels |

| Handheld RFID Reader | Fast manual reading | Portable, PPE-compatible, screen visible with ice |

| RFID Portal | Real-time flow control | Detects moving products, even stacked items |

When all these tools work together, your cold storage becomes a smart traceability system — built to perform even when the thermometer hits -18 °C.

And the best part? All this data feeds into dashboards, automatic reports, and smart alerts — no more clipboards or wasted time inside freezing rooms.

Want help choosing the right RFID tools for your cold storage facility?

Our team will guide you through the ideal setup for maximum performance.

Automation in refrigeration: overcoming cold chain challenges

Automating a refrigeration facility isn’t just about installing machines and pushing buttons. It means facing head-on an environment where nothing can go wrong — temperature, humidity, timing, traceability, and food safety all have to work together, like a Swiss watch… running inside a freezer.

And that’s exactly where RFID automation shows its strength.

What seems simple on paper becomes a real challenge in daily operations:

- Gloves and protective gear make it harder to handle scanners or tablets

- Condensation ruins paper labels and handwritten records

- Cold rooms require speed — no one can stay inside for long

- Orders must be picked with precision, even when products look nearly identical

Now imagine solving all of that with a system that can scan hundreds of items at once, withstand cold, and send updates in real time — without touching a single box.

RFID makes that possible. But it goes beyond inventory.

It also improves how different teams communicate. Shipping knows what’s ready to go. Management sees stock turnover in real time. And audit reports for regulators are just a few clicks away, with complete and accurate data.

Automation doesn’t just make life easier — it turns cold chain logistics into a smarter, safer, and faster operation.

Real-world benefits of RFID for the meat industry

When we talk about RFID, we’re not talking about some far-off future. We’re talking about real, immediate gains. Companies that adopt RFID in their cold storage operations see the difference right away — both in daily workflow and in their bottom line.

Here are the biggest benefits RFID brings to meat processing and distribution:

1. Fewer losses from expired products

With automatic traceability, the system shows which batches are close to expiration. That means fewer forgotten items, and products get moved before it’s too late.

2. Faster, more accurate inventory

What used to take hours — or even days — can now be done in minutes. And with no typos or missed items. Whether boxes are stacked or hidden, RFID finds them.

3. Less time spent in freezing rooms

RFID does the reading for you. Workers don’t have to stay in cold environments for long periods, which reduces health risks, accidents, and time wasted.

4. Full visibility of your stock

At any moment, managers can check how much inventory is in each room, how long it’s been there, and what’s ready to ship. That kind of control changes everything.

5. Easy integration with existing systems

RFID connects smoothly to your ERP, management dashboards, and logistics platforms. You don’t need to start from scratch — it enhances what you already use.

6. Faster and more accurate order fulfillment

Orders are picked quickly and correctly. The risk of shipping the wrong batch drops dramatically. That means happier customers and a more efficient operation.

7. Always audit-ready

With everything automatically recorded, your facility is ready for inspections — whether it’s the health department, the agriculture ministry, or international buyers.

In short, RFID isn’t just a tech upgrade. It’s a smart strategy for better performance, lower risk, and long-term competitiveness.

And the best part: this technology is already available. It works, it scales, and it can be customized to fit your operation.

The role of RFID tags in quality and durability control

RFID tags are the core of a reliable traceability system. They’re not just simple labels — they carry the key data that ensures every product is tracked with accuracy: what it is, where it came from, when it entered the system, and when it expires.

In cold storage, RFID tags must go beyond basic performance. They need to be tough, precise, and built for extreme conditions.

Here’s why that matters:

Picture a box of frozen meat moving through humid environments, chilling tunnels, stacking areas, and multiple loading docks.

A regular paper label would fall apart. But a cold-resistant RFID tag keeps working, even at -25 °C and in high humidity.

RFID tags ensure:

- Reliable data retention, even in harsh environments

- Contactless reading, reducing human error and speeding up processes

- End-to-end traceability, from processing to shipping

- Real-time quality control with data that powers automatic reports

These tags also adapt to different types of packaging — plastic bags, returnable crates, trays, and pallets.

At CPCON, we use RFID tags specifically tested for cold room operations, ensuring your traceability system won’t fail — even under the toughest conditions.

And the best part?

RFID tags work seamlessly with antennas, handheld readers, and smart dashboards. That means your quality control is no longer at risk — it becomes one of your strongest assets.

Want to explore how RFID technology is transforming operations in different industries?

Check out these related articles from CPCON Group:

- RFID Inventory Management: Learn how to reduce costs and improve operational performance

- How to control inventory with RFID for American football clubs?

- RFID and AI in healthcare: Discover how to optimize hospital operations

How CPCON implements RFID with precision and reliability

In cold storage environments, accuracy and speed in inventory management aren’t optional — they’re critical. But how do you ensure that in a freezing, high-turnover, and often humid setting?

At CPCON, our answer is clear: the right technology, in the right place.

We deliver a complete RFID solution, including cold-resistant tags, antennas installed at strategic points, and rugged handheld readers. All of it integrated into a system that enables:

- Fast and error-free inventory counts

- Real-time tracking of product movement

- Instant visibility of expiration dates, batches, and stock locations on a centralized dashboard

Our RFID tags are specially designed to withstand extreme conditions, providing consistent performance even with frost, condensation, or heavy stacking.

With CPCON’s technology, cold storage facilities reduce worker exposure to freezing temperatures, improve productivity, save time and money — and gain full control over quality and inventory.

Less risk. More efficiency. All under control.

See how it works in real time

Watch how CPCON’s RFID solution performs in freezing environments, with cold-resistant tags, smart antennas, and accurate readers in action.

The future of RFID in cold storage: more data, more control, more value

RFID is no longer a novelty — it’s becoming the new standard for cold storage facilities aiming for efficiency and growth. But what’s next? The answer is clear: data.

In the near future, facilities using RFID will go far beyond basic inventory control. They’ll be able to:

- Analyze average storage times for each product

- Cross-reference data on temperature, humidity, and movement in real time

- Predict waste before it happens

- Make smarter decisions through dashboards, alerts, and automated insights

In other words, RFID evolves from a tracking tool into a strategic engine for data-driven decision-making.

And that changes everything.

Companies embracing this approach gain agility in audits, negotiating power with distributors, and the ability to reduce operational costs — all based on solid, real-time information.

At CPCON, we believe this is the path forward: turning technology into real competitive advantage.

That’s why we continue improving our systems, enhancing ERP integration, and delivering fully customized RFID projects — always with a focus on traceability, quality, and performance.

Because in the future of cold storage, those who control the data will lead the market.

Ready to implement a complete RFID solution with proven results?

Let CPCON Group help you gain total visibility and efficiency.

FAQ

What is RFID and how does it work in cold storage facilities?

RFID is a radio frequency identification technology. In cold storage, it allows meat products to be tracked automatically — by expiration date, batch, and location — without needing physical contact or line of sight, even inside freezing rooms.

What are the main benefits of using RFID for inventory control?

RFID makes inventory counts faster, more accurate, and fully automated. It reduces manual errors, cuts losses from expired items, and gives you real-time visibility into your stock and operations.

Does RFID work in freezing and humid environments?

Yes. RFID tags designed for cold storage are built to resist extreme temperatures, moisture, and condensation. They remain functional even at -25 °C, ensuring reliable data capture in challenging conditions.

How is RFID different from barcode systems in refrigerated areas?

Barcodes require manual scanning and clear visibility. RFID reads multiple items at once, from a distance, without needing to see the label. It also works better with gloves, stacked products, and wet surfaces.

Can RFID integrate with my existing ERP system?

Absolutely. CPCON’s RFID solutions are compatible with most ERP systems and can be integrated into your existing inventory, logistics, and compliance workflows.

Is RFID a good investment for mid-sized cold storage businesses?

Yes. Even mid-sized operations can see strong returns with RFID — through reduced waste, faster workflows, and better traceability, especially in industries with strict health and export regulations.

How can CPCON help implement RFID in my cold storage facility?

CPCON provides a full-service solution: technical analysis, cold-resistant RFID tags, antennas, handheld readers, and seamless system integration — all backed by expert support to ensure reliable, scalable implementation.