.

Visual asset control is the ability to see and manage physical assets in real time using interactive maps, digital tags, and integrated systems. Instead of relying on static spreadsheets, companies can now visualize the exact location, condition, and usage of each asset across plants, warehouses, or field operations.

This shift is not just about better tools — it’s about better decisions. In global operations with thousands of moving assets, the lack of visibility creates risk: misused equipment, delayed audits, unexpected downtime, and costly inefficiencies.

Visual asset control solves that. It brings clarity to complexity, turning asset data into visual intelligence that supports faster audits, smarter relocations, and stronger financial planning. And with technologies like RFID, GIS, and BIM, this is no longer a future trend — it’s a current advantage.

During this article, you’ll learn:

- What visual asset control is and how it works

- Why it’s essential for complex, multi-site operations

- Which technologies support real-time visualization

- How to implement it step by step

- And how CPCON Group helps companies turn visibility into strategy

Table of Contents

ToggleWhat Is Visual Asset Control and How Does It Transform Asset Management?

Visual asset control is a strategy that connects physical assets to their real-world location through digital visualization. It combines inventory data, geolocation, and real-time tracking into one interactive platform — allowing companies to truly see what they own, where it is, and how it’s performing.

Instead of looking at rows in a spreadsheet, asset managers can now open a map and view every piece of equipment in context: in a plant layout, a building floor plan, or a large outdoor site.

What makes this different from traditional asset control?

Traditional asset management relies on static records and periodic updates. Visual asset control gives you continuous access to live data — visualized through systems that integrate RFID, GPS, BIM, or GIS.

Let’s look at a real-world scenario:

A logistics company operates across five distribution centers. During an internal audit, the team is asked to verify the location and condition of hundreds of mobile assets. With traditional methods, this would take days. With visual asset control, they filter by asset type and instantly see the exact placement and usage history of each item — on-screen, on a map.

How Visual Asset Control creates strategic value

This isn’t just about seeing assets. It’s about making better decisions. When you visualize your asset infrastructure, you can:

- Optimize layout and space usage

- Detect idle or underutilized equipment

- Plan maintenance schedules based on real usage

- Identify gaps in capacity or storage

- Support audits with georeferenced evidence

Can you really manage what you can’t see? Visual Asset Control answers that question by making asset visibility part of your everyday decision-making process.

Key Benefits of Visual Asset Control for Complex Operations

In large, multi-site organizations, losing track of physical assets is more common than most people realize. Equipment gets misplaced, forgotten, or duplicated. Maintenance is delayed. Audit teams struggle to verify information. The root cause? Lack of visibility.

Visual asset control solves this by bringing clarity to every corner of the operation — from the warehouse to the production floor, from regional offices to field assets.

What problems does it actually solve?

When you can’t see your assets, you face risks like:

- Lost or stolen equipment

- Inaccurate depreciation and financial reporting

- Inefficient maintenance cycles

- Poor space utilization

- Costly delays in audits or reallocation

Now imagine being able to see, on a digital map, the exact position, condition, and usage of every asset — in real time.

That’s what Visual asset control enables.

Top benefits of adopting a visual control system

Let’s break down the practical advantages:

- Real-time visibility across all locations

You get a live view of your asset infrastructure, no matter how large or spread out. - Faster, more reliable audits

Auditors can cross-reference mapped data and system records instantly. - Reduced losses and unplanned purchases

When you know what you have — and where it is — you avoid buying what you already own. - Improved space management

Facility managers can reorganize layouts based on actual asset placement. - Data-driven planning

Strategic decisions (CAPEX, relocations, maintenance) become faster and more accurate.

The bigger the operation, the greater the impact

If your company manages multiple plants, warehouses, or field sites, the value of seeing your assets — not just listing them — increases exponentially.

In these environments, visual asset control isn’t a luxury. It’s a competitive advantage.

How Visual Asset Control Works: From Mapping to Real-Time Tracking

Visual asset control works by linking physical assets to their exact position in your facility — digitally and dynamically. It’s not just about recording data. It’s about embedding every asset into a visual, interactive system that reflects your actual operation.

This process doesn’t require a massive overhaul, but it does require structure. Here’s how it works in practice, step by step.

Step 1: Physical identification and data capture

The process begins by tagging all relevant assets using identification technologies such as:

- RFID tags for automatic, non-line-of-sight scanning

- QR codes or barcodes for simpler or low-frequency tracking

- Specialized metal or durable tags for industrial and outdoor environments

Each tag is linked to key data points:

- Unique asset ID

- Category and description

- Location, department, and assigned user

- Acquisition date, condition, and lifecycle status

Step 2: Mapping assets to real-world layouts

Next, assets are embedded into digital floor plans or 3D models of the facility:

- You can use a digitized plant layout, CAD file, or BIM model

- Assets are pinned to their actual locations on the map

- Layers of data are added: usage, maintenance, movement history, etc.

Step 3: Integrating with business systems

Visual asset control doesn’t work in isolation. It becomes powerful when integrated with:

- ERP systems (like SAP, Oracle, or Totvs)

- Maintenance platforms (preventive and corrective routines)

- Procurement and finance systems (for depreciation and CAPEX planning)

- IT asset management or CMDBs (especially in digital infrastructure)

Step 4: Real-time monitoring and decision support

Once mapped and integrated, the system becomes a live, interactive dashboard that:

- Tracks asset movements in real time (especially with RFID)

- Flags deviations or unauthorized removals

- Supports audits with georeferenced evidence

- Provides insights on idle assets, maintenance due, or layout inefficiencies

Visibility is the New Pillar of Modern Asset Management

You can’t manage what you can’t see. That’s not just a saying — it’s the hard truth for companies that still rely on disconnected spreadsheets or outdated systems to track their assets.

Today’s asset-intensive operations demand more than control. They demand real-time visibility: knowing not just what you own, but where it is, who’s using it, and whether it’s still performing.

The real risk isn’t loss — it’s invisibility

Many companies don’t realize they’re losing money simply because they can’t see where their assets are.

Think about it:

- How many unused machines are occupying space?

- How often are audits delayed by missing items?

- How many times has equipment been replaced simply because it was “lost”?

Visibility brings operational intelligence

When you can see your assets in context — in real-time, on a map, connected to systems — you gain:

- Control: instant knowledge of asset status and location

- Accuracy: fewer manual errors and outdated records

- Responsiveness: ability to act quickly on movement, misuse or changes

- Strategic insight: use data to plan layouts, maintenance and investments

This transforms asset management from a reactive task into a proactive strategy.

Visibility is no longer optional

In complex operations, the lack of visibility means:

- Increased audit risks

- Redundant purchases

- Unreliable compliance reporting

- Blocked growth due to unstructured infrastructure

And yet, many companies still treat visual control as a “nice to have.” But in truth, visibility is now the baseline. It’s the starting point for any reliable, scalable asset management process.

RFID, GIS and BIM: The Technologies Behind Visual Asset Control

Visual asset control is only possible because of three key technologies that bring physical reality into digital systems: RFID, GIS and BIM. Each one plays a specific role in mapping, tracking, and managing assets with precision — and together, they create a powerful ecosystem of visibility and control.

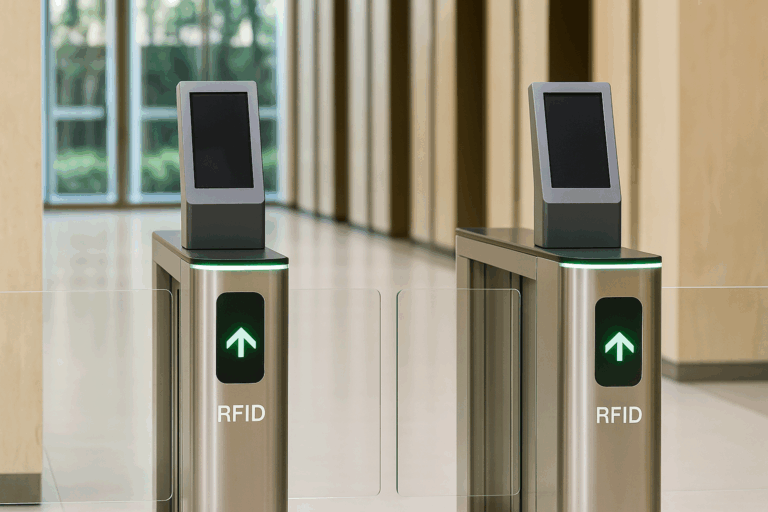

RFID: Real-time identification without line of sight

Radio Frequency Identification (RFID) allows assets to be identified automatically — even if they’re not directly visible.

- Tags are attached to each asset

- Fixed or mobile readers scan them using radio waves

- Data is collected instantly and sent to the central system

This eliminates manual checklists, speeds up inventory, and detects unauthorized movements in real time.

In a single scan, RFID can verify the presence of hundreds of assets — with no need to see or touch each one.

GIS: Geospatial intelligence for large-scale operations

Geographic Information Systems (GIS) bring location awareness to the next level — especially for companies with outdoor operations, multiple campuses or distributed facilities.

- Assets are plotted using GPS coordinates

- Maps show their position in real-world context

- Movement and usage can be monitored over time

GIS is critical for industries like energy, utilities, construction, transportation, and mining — where control extends far beyond the four walls of a plant.

BIM: Building-level visualization and planning

Building Information Modeling (BIM) adds a 3D layer to visual asset control — enabling high-resolution mapping inside buildings, factories, or complex infrastructure.

- Assets are positioned within a digital replica of the environment

- You can plan layout changes, renovations or expansions visually

- Maintenance, usage and structural data can be layered into the model

BIM is especially powerful in hospitals, universities, manufacturing plants and data centers, where spatial accuracy is critical.

Together, these technologies unlock full visibility

When combined in a unified system, RFID, GIS and BIM allow your team to:

- View assets in real time

- Track their movement and usage

- Detect risks before they escalate

- Make layout, budget and compliance decisions based on real-world data

Critical Scenarios Where Visual Asset Control Makes the Difference

There are moments when the lack of asset visibility becomes more than an inconvenience — it becomes a risk. In these scenarios, visual asset control helps companies avoid costly errors, regulatory issues, and operational bottlenecks.

Let’s explore when this approach makes the biggest impact.

Audits and regulatory inspections

When auditors or regulators ask, “Can you prove this asset exists and is in use?”, the answer must come quickly and with evidence.

Without visual asset control:

- Audit prep is manual and time-consuming

- Missing or misplaced items trigger non-compliance alerts

- Financial reporting becomes vulnerable to inconsistencies

With visual systems, every asset is mapped, documented, and instantly retrievable.

Mergers, acquisitions, and internal restructuring

During corporate changes, asset records must be consolidated, validated, and reallocated. The risk of duplication, ghost assets or valuation errors is high.

Visual asset control enables:

- Fast reconciliation of records and physical assets

- Smooth integration of asset data from both organizations

- Informed decisions on divestment or redeployment

Facility expansions and layout changes

When a plant grows or operations are restructured, knowing how space is used — and which assets are where — is critical.

Without that visibility, companies may:

- Over-purchase equipment

- Underutilize existing assets

- Delay layout planning due to lack of data

Mapped visual data accelerates facility design, zoning, and investment planning.

Multi-site or field-based operations

If your assets are distributed across cities, campuses, or outdoor locations, relying on manual reporting is no longer viable.

Visual asset control provides centralized, real-time oversight — even when operations are decentralized.

The team at headquarters can see what’s happening in the field, without needing to be there.

Step-by-Step: How to Implement an Effective Visual Asset Control System

Implementing visual asset control doesn’t require reinventing your entire operation. It’s about following the right sequence — combining identification, mapping, integration and continuous improvement.

Here’s how companies typically begin, scale and optimize.

Step 1: Define what needs to be visible

Start by identifying which asset groups will bring the highest impact when made visible:

- High-value or mobile assets

- Equipment with frequent maintenance or movement

- Assets across multiple buildings, plants or remote sites

- Items involved in audits, insurance or compliance

This focus helps prioritize where visibility creates the most value first.

Step 2: Standardize asset identification

Choose the right tagging method based on your environment:

- RFID for automated, contactless tracking

- QR codes or barcodes for indoor assets with manual checkpoints

- Durable metal tags for industrial or outdoor assets

Make sure every tag includes a unique ID and links to key data (location, category, lifecycle, cost center, responsible department).

Clear identification is the foundation of a reliable visual system.

Step 3: Build your visual asset map

Using existing layout files (PDF, CAD, BIM, GIS), place each tagged asset into its physical context:

- Map rooms, zones, plants or outdoor coordinates

- Assign visual markers based on asset type or status

- Set user permissions and alerts for updates or movements

Step 4: Integrate with business systems

Your visual control gains power when connected to:

- ERP (asset register, depreciation, budget planning)

- Maintenance management platforms (preventive and corrective tasks)

- IT and procurement systems (lifecycle, warranties, requests)

- Compliance systems (auditing, risk, insurance)

This integration ensures asset data is not only visible — it’s actionable.

Step 5: Establish routines for audit and updates

To keep the system alive and accurate:

- Schedule regular visual audits using RFID scans or mobile apps

- Set alerts for movement, status change or inactivity

- Train stakeholders to use and rely on the visual dashboard

How CPCON Group Delivers Real-Time Visibility and Strategic Asset Control

At CPCON Group, visual asset control isn’t a buzzword — it’s our daily delivery. We combine over 25 years of technical expertise with advanced technologies like RFID, GIS and BIM to transform how organizations manage their physical assets.

Whether your company operates a single site or a global infrastructure, our goal is clear: give you the power to see, control and optimize every asset in real time.

A complete solution from identification to visualization

Our service is end-to-end. We don’t just offer software — we deliver structure, technology and long-term control.

- Asset tagging and technical cataloging (RFID, QR code, custom labels)

- Digital mapping of physical spaces (plant layouts, BIM, GIS integration)

- Platform with real-time dashboards and georeferenced views

- System integration with ERP, CMMS, and compliance tools

- Support from planning to post-implementation audits

Whether you need to prepare for an audit, restructure your operations or improve lifecycle visibility, CPCON delivers clarity where others offer complexity.

Why global companies choose CPCON

- Proven experience with multinational clients across manufacturing, energy, healthcare, retail and logistics

- Customizable solutions adapted to each organization’s structure and maturity level

- Technical consultants and engineers guiding every step of the project

- Focus on ROI, compliance and long-term reliability — not just technical implementation

As our Innovation Director Alexandre Brito says:

“If you can’t see it, you can’t control it.” That’s the principle we help our clients apply, every day.

Ready to make your asset management visible and strategic?

Talk to CPCON Group and discover how visual asset control can bring real-time clarity to your operation.

Visibility Is Strategy: Why Visual Asset Control Is No Longer Optional

In today’s asset-intensive operations, visibility is the foundation of control, compliance and efficiency. Without it, even the most advanced systems become blind. With it, decisions become faster, audits become easier, and risks become manageable.

Throughout this article, you’ve seen that:

- Visual asset control brings clarity to complex operations

- Technologies like RFID, GIS and BIM make real-time tracking possible

- The benefits go beyond efficiency — they support risk reduction and better investment decisions

- Implementation is scalable and structured, not disruptive

- CPCON Group is a strategic partner that delivers real results, not just reports

Seeing your assets isn’t a luxury — it’s the new standard. And it starts with taking control of what you can see.

Want to explore more insights on smart asset management?

Browse our blog and discover how technology is reshaping control, compliance, and efficiency:

- Automating asset tracking: best practices for implementation

- How a Strategic Asset Inventory Helped GE Unlock Smarter Capital Maintenance Budgeting

- Impairment in the Agricultural Sector: Asset Valuation that Ensures Compliance and Security for your Assets

FAQ

What is visual asset control?

Visual asset control is a system that allows companies to see their physical assets in real time through digital maps, geotagged data, and interactive platforms. It shows where assets are, how they’re used, and their condition — all in one place.

How is visual asset control different from a traditional asset inventory?

Traditional inventories are static lists updated periodically. Visual asset control is dynamic, giving you a live view of asset locations, usage, and movement — often integrated with technologies like RFID, GIS or BIM.

Which industries benefit the most from visual asset control?

Industries with complex operations and multiple locations benefit most: manufacturing, healthcare, logistics, energy, education, and government — especially those requiring audits or compliance reporting.

Do I need to replace my ERP or maintenance systems to use visual asset control?

No. Visual asset control is designed to integrate with existing systems like SAP, Oracle, Totvs, CMMS or ITAM platforms — adding a visual layer on top of your current infrastructure.

How does CPCON Group help implement visual asset control?

CPCON Group delivers end-to-end support: asset tagging, mapping, system integration, visual dashboards, and audit preparation — all customized to your operation, with expert consultants guiding every step.

Visual asset control is a modern approach to asset management that turns physical asset data into real-time, map-based visualizations. It helps organizations locate, monitor, and manage their assets more effectively using technologies like RFID, GIS, and BIM. This system improves audit readiness, reduces operational risk, and supports data-driven decisions. With step-by-step implementation and integration into existing systems, CPCON Group enables companies to gain full visibility and strategic control over their physical infrastructure.