Want to turn improvisation into planning and chaos into efficiency? A reliable production management software connects every stage of the operation, boosts productivity, and brings predictability to your results. In this article, you’ll understand why this technology has become essential for companies that aim to grow with control and profitability.

Do you manage your production — or are you constantly putting out fires? That’s a question keeping many industrial managers up at night. After all, at the heart of an efficient factory, it’s not just machines running or workers racing against time. It’s an intelligent system capable of transforming data into decisions — and chaos into control.

Today, the key difference between industrial companies that grow consistently and those that merely survive lies in predictability. And on the shop floor, predictability is only possible with production management software. It’s not just about technology. It’s about leading strategically, safely, and efficiently. With the right production management software, it becomes possible to detect failures before they happen and turn improvisation into planning.

Table of Contents

ToggleWhat is production management software?

Picture a factory where the production manager still depends on manual spreadsheets, urgent phone calls, and scattered notes to keep everything working.

The team rushes through the day, constantly reacting to problems rather than anticipating them. And at the end of the day, one question remains: did we deliver everything correctly?

This is exactly where production management software comes in — a solution that transforms chaos into efficiency on the shop floor.

It connects every stage of the operation, from receiving inputs to delivering the final product, through real-time data, traceability, and automation. What used to be managed by intuition is now driven by precision — where decisions stop being guesses and become strategies.

With such a system, production stops being a series of emergencies and becomes predictable, efficient, and profitable. The manager gains complete visibility into the operation, identifies bottlenecks easily, and increases team productivity. In the end, it’s all about smart leadership — not just putting out fires.

What is the best production management software?

The best production management software is the one that delivers visual simplicity, real-time control, and full traceability of processes.

Contrary to what many imagine, managing production doesn’t have to be complex. It has to be agile. And most importantly: it has to be reliable.

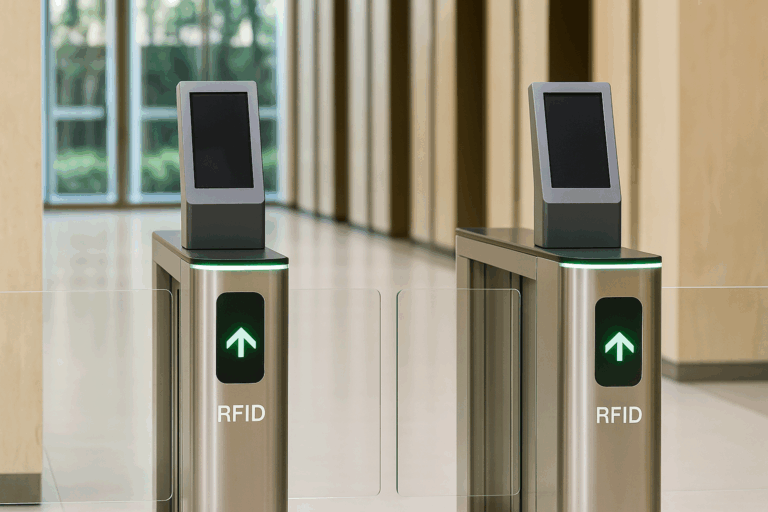

Imagine a production line where each input is tracked as soon as it arrives. Where materials can be approved or rejected with a click. Where traceability is ensured through RFID or QR codes. And all of this is integrated with suppliers and quality control teams.

Sounds like science fiction? It’s the daily reality of companies that rely on intelligent production management. With this type of system, you can:

- Better plan production cycles;

- Reduce waste and rework;

- Improve efficiency on the shop floor;

- Automate repetitive operational tasks;

- Make data-based decisions with confidence.

What are the best tools for production management?

The most essential features of modern production software cover the entire operational cycle — from receiving raw materials to final delivery.

The goal is to ensure every stage happens in a coordinated, safe, and efficient manner. Key features include:

- Input and material control: ensures only compliant materials enter production.

- Kit and component assembly: enables fast configuration of lots and production flows.

- Real-time quality control: allows for quick decision-making to avoid downstream errors.

- Process traceability: with QR codes and RFID, each item can be tracked throughout its journey.

- Automated management reports: provide analytical insights to support decision-making.

A quality solution also includes efficient production planning, performance tracking, and seamless integration with ERP and CRM systems.

What are the 4 types of production control?

To maintain a profitable operation, it’s important to understand the four main types of control a system should support:

- Input Control: Monitors the arrival, stock, and quality of materials. Supports input management and avoids stockouts or overstocking.

- Quality Control: Ensures products meet required technical and safety standards.

- Process Control: Tracks the progress of each production stage, enabling industrial automation and transparency.

- Final Product Control: Ensures finished goods are delivered safely and on time, with complete traceability and customer satisfaction.

These four pillars are essential for sustainable and scalable industrial productivity.

CPCON’s Solutions for Industrial Process Optimization

Understanding the daily challenges of the industry, CPCON developed a complete production management software based on real experiences from managers dealing with outdated spreadsheets, manual processes, and decisions made on gut feeling.

The result? A robust yet easy-to-use platform. With features ranging from input management to full process traceability, plus real-time dashboards and smart controls.

“We’ve seen operations go from chaos to predictability. Our system helped companies reduce downtime by 35% and increase productivity by up to 50% in under six months.” Iasmim Godoy, IT Director at CPCON

Beyond the technology, CPCON offers something many platforms don’t: personalized support. Our team works alongside clients, mapping processes and building tailored workflows for each type of industry.

Conclusion

Whether your company manufactures auto parts, hospital equipment, or cosmetics — if there’s a production line, there’s an opportunity for improvement. And that starts with reliable production management software.

It’s not just about automation. It’s about strategy. Turning your processes into a controlled, predictable system. Ending emergency mode and building a scalable, profitable operation.

So the final question is: Is your production truly under your control — or buried in someone’s spreadsheet?

Speak with CPCON’s experts and request a free demo of our production management software. Discover how to make your production line smarter, more traceable, and more profitable.

FAQ – Production Management Software

What is production management software?

It’s a digital tool that organizes and automates every stage of production — from inputs to delivery — with real-time data, traceability, and strategic decision-making.

What are the benefits of using production management software?

It reduces waste, improves productivity, increases shop floor efficiency, enables traceability, and supports smarter business decisions.

How do I choose the best software for my company?

Look for a solution with visual simplicity, real-time operational control, and integration with other systems — one that fits your production reality.

What features should a good production software include?

Input tracking, RFID or QR code traceability, dashboards, quality control tools, and automated reports for efficient planning.

Is production management software suitable for companies of all sizes?

Yes. Scalable systems adapt to both small manufacturers and large industrial operations with multiple lines.

What are the four main types of production control?

Input control, quality control, process control, and final product control — the foundation of efficient production management.

How does CPCON support implementation?

Beyond technology, CPCON offers personalized consulting, process mapping, and custom solutions tailored to each industry’s needs.