How can you stop unexpected fleet breakdowns and cut operating costs at the same time? MRO logistics inventory is the smart answer! It makes sure parts, tools, and supplies are always ready, making fleet maintenance better and keeping your road freight operations running smoothly.

MRO logistics is all about managing the materials you need to keep your logistics activities maintained, repaired, and operational. This includes everything from spare parts for vehicles to special tools and everyday items like lubricants and safety gear (PPE). Without careful control of these technical supplies, companies in this sector face unplanned stops, higher costs, and the risk of not meeting rules and regulations.

In a world where efficient logistics is key to staying competitive, MRO inventory becomes a vital foundation to prevent operational failures and keep your fleet available. It’s more than just a support task; it’s a strategy to keep performance high, ensure tracking, and maintain compliance from start to finish.

In the next sections, we’ll dive deeper into how managing MRO logistics affects costs and compliance in road transport. We’ll look at the main challenges maintenance teams face and how tech solutions – like RFID – are changing how this type of inventory is managed. We’ll also see how CPCON helps turn this control into a real competitive edge.

Table of Contents

ToggleWhat is MRO Logistics and Why Is It Essential in Road Transport?

MRO in logistics stands for Maintenance, Repair, and Operations, but applied specifically to the world of logistics. It covers all the supplies, parts, and tools needed to keep transport operations running smoothly.

In the road transport sector, MRO makes sure your fleet is available, safe, and technically sound. This includes everything from tires, filters, and engine parts to support equipment like torque wrenches and electronic devices.

Even though it’s often overlooked, MRO inventory directly impacts how efficient your routes are and helps cut down on unexpected breakdowns. Without proper control, simple failures can lead to logistics delays, financial losses, and even broken contracts with shippers.

What’s more, not having a structured MRO management system means you can’t really see what materials are being used, which makes it tough to restock strategically. This leads to pricier emergency purchases and the risk of items in stock becoming outdated.

For companies with hundreds of vehicles, like large trucking firms and logistics operators, a lack of reliable technical inventory makes management even more complex. Operations become reactive instead of proactive, which drives up costs and exposes the company to regulatory risks.

That’s why MRO in the logistics sector can’t be treated as just another cost center. It’s a critical part of your operational setup, directly influencing fleet performance, meeting service agreements (SLAs), and your company’s reputation in the market.

How Smart MRO Inventory Boosts Your Fleet’s Performance

A well-managed MRO inventory makes a huge difference in road transport operations. It ensures that parts and supplies are available exactly when needed, preventing delays caused by mechanical failures or missing components.

When control fails, the impact is immediate: vehicles sit idle, routes are interrupted, and deadlines are missed. Every hour a vehicle is out of action means lost income, higher costs, and damage to customer relationships.

Your fleet’s performance relies on predictable operations. And that’s only possible with a technical inventory system that tracks part usage, manages restocking levels, and flags items that are running low.

What’s more, MRO control helps prevent waste. Many companies buy too many items out of fear of running out, ending up with shelves full of expired or unused parts. This idle stock represents money tied up with no return.

Another key strategic point is traceability. With a digital inventory linked to maintenance, you can know exactly where each item was used, when it was replaced, and its history of consumption.

This visibility also empowers better decision-making. With accurate data, managers can plan purchases more effectively, negotiate with suppliers, and even anticipate maintenance needs before bigger problems pop up.

Ultimately, a well-structured MRO isn’t just about supporting maintenance. It’s a performance driver that keeps your fleet moving, cuts costs, and protects your company’s reputation with demanding clients and strict inspections.

Key Challenges in Managing Logistics Parts, Tools, and Supplies

Why is it so tough to keep track of logistics supplies? Because, in reality, MRO inventory demands integration, traceability, and standardization—and most companies still operate without these key pillars.

1. Lack of Centralization and Visibility

When parts, tools, and supplies are scattered across different branches, garages, and even truck compartments, control becomes nearly impossible. The company loses sight of where each item is, who used it, and when it’ll need to be replaced.

2. Manual or Outdated Systems

Spreadsheets, separate tracking methods, and non-integrated software are frequent sources of error. Information gets lost, isn’t updated in real-time, and creates bottlenecks in purchasing and maintenance decisions.

3. Fast Consumption and High Turnover

Lubricants, filters, PPE, and daily-use tools have a high consumption rate. When there isn’t a reliable technical inventory, getting these supplies becomes a problem—leading to urgent needs, inflated prices, and the risk of fleet downtime.

4. Missing Tools and Improper Use

Without traceability, tools disappear, are used incorrectly, or don’t return to stock. This leads to unnecessary replacements, higher costs, and hurts team productivity.

5. Lack of Standardization in Management

Each unit or workshop might follow different processes, lacking consistent criteria for recording, storing, or replacing items. This reduces efficiency, complicates audits, and makes operational control unsustainable.

6. Fiscal Risk and Non-Compliance

MRO control involves technical and regulatory requirements. It’s necessary to record validity, track batches, and meet standards from ANTT, Inmetro, and ISO. A lack of compliance can result in fines, penalties, and lost contracts.

How MRO Inventory Cuts Operating Costs in Road Logistics

Smart MRO management in logistics doesn’t just prevent waste; it directly lowers your fleet’s operating costs. When a company accurately controls its technical supplies, the financial impact is clear, measurable, and ongoing.

1. Fewer Emergency Buys & Stronger Negotiation Power

With a well-organized inventory, you can predict the perfect time to restock parts and supplies. This helps you avoid last-minute, higher-priced purchases and allows for bulk negotiations with suppliers.

- Companies that switched from emergency buys to planned purchases report significant savings per item.

- You can take advantage of contracts with volume discounts and special delivery terms.

2. Preventing Breakdowns & Reducing Fleet Downtime

One of the biggest costs in road logistics is when your fleet isn’t moving. With up-to-date MRO control, your company can anticipate replacements and prevent unexpected failures.

- This leads to fewer unplanned stops.

- It improves route reliability and helps you meet service agreements (SLAs) with clients.

3. Cutting Down on Losses, Missing Items, and Improper Use

Without tracking, tools and parts disappear, are used incorrectly, or vanish from stock. A technical inventory using RFID or barcodes solves this problem.

- Using RFID significantly reduces lost items and improves control over technical inventory.

- You can track usage by employee and by the type of maintenance performed.

4. Less Money Tied Up in Idle Stock

Idle stock is idle money. With accurate data on turnover, expiration dates, and actual use of each item, your company only buys what’s needed.

- This frees up physical space and lowers storage costs.

- You gain more available cash by avoiding the accumulation of unused or outdated parts.

5. Streamlining Maintenance Teams and Processes

Smart MRO inventory makes it easier for maintenance teams to organize their work, letting them spend less time searching for materials and more time on strategic tasks.

- Boost productivity with automated processes.

- Reduce the workload for stockroom staff and maintenance technicians.

Regulatory Compliance and Audits: The Role of Well-Managed MRO

Did you know that a slip-up in parts control can lead to more than just operational losses? It can also result in legal penalties! For transport companies, staying compliant with regulations directly depends on efficient MRO logistics management.

1. Legal Demands in Road Transport

Companies in this sector must follow rules from agencies like ANTT and Inmetro, along with environmental and labor safety bodies. This includes tracking critical parts, controlling the expiration dates of supplies, and recording all maintenance performed.

- Filters, oils, and tires have expiration dates and technical specifications that must be followed.

- Some parts require proof of origin, batch, and where they were used in vehicles.

Without this information organized, your company faces risks during inspections and audits. Missing data can lead to fines, your fleet being held back, and even lost logistics contracts.

2. How MRO Inventory Ensures Compliance

A technical inventory system centralizes information, making it easy to quickly access data required by auditors and regulatory bodies. Every item has a record of its arrival, departure, destination, and use.

- With RFID, you can locate any part in seconds.

- All data is saved, organized, and ready for auditing.

This speeds up response times, boosts transparency, and shows maturity in logistics management. This is increasingly valued in certification processes, contracts with shippers, and ESG requirements.

3. Safety and Standardization in Using Supplies

MRO control also protects your operation from using incompatible or non-standard parts. This prevents mechanical failures, accidents, and labor liabilities.

- The right parts, at the right time, ensure safety on the roads.

- It avoids last-minute improvisations due to missing materials, which is common in disorganized operations.

Beyond reducing risks, this standardization strengthens your company’s image with clients, partners, and regulators. Being known for well-structured technical management is a competitive advantage in the industry.

The Power of Technology in MRO Inventory: RFID and Logistics Automation

Managing parts and supplies manually is a tough, time-consuming task prone to mistakes. With the right technology, MRO inventory in logistics stops being a bottleneck and becomes a source of operational efficiency.

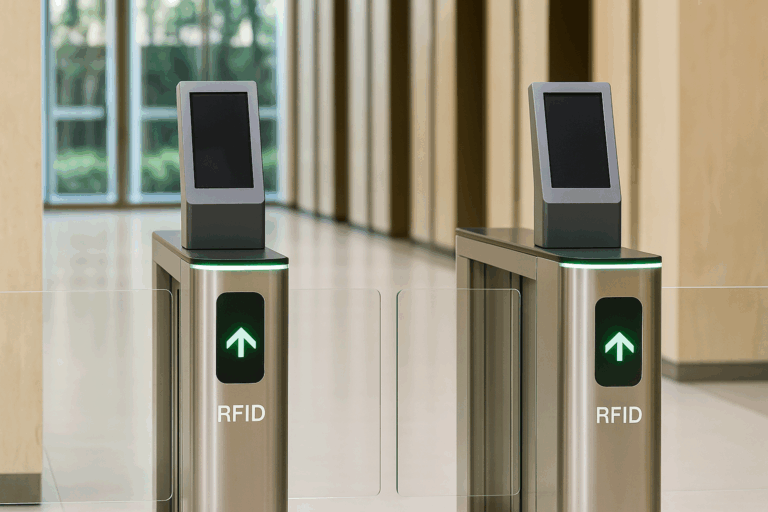

1. How RFID Works for Parts and Supply Control

RFID (Radio Frequency Identification) technology lets you track parts, tools, and materials in real time, without having to scan each item individually. Every component gets a smart tag that sends data to your management system.

- Just walk past an RFID gate or bring a reader close to automatically update your inventory.

- The system shows what came in, what went out, where it went, and when it needs to be restocked.

This visibility eliminates recording errors, cuts down on control time, and prevents the use of unauthorized or expired parts.

2. Benefits of Logistics Automation in MRO

Beyond RFID, other technologies like sensors, fixed readers, integrated systems, and cloud-based dashboards help automate the MRO control process.

- Warehouses become more agile, quickly locating parts.

- Managers can track technical stock levels in real time at each location.

- Automatic alerts notify you about critical items or those nearing expiration.

Automation reduces rework, improves data accuracy, and prevents unpleasant surprises in your operations.

3. Integration with Maintenance Systems and ERP

Inventory technology can (and should) be integrated with existing systems, like ERPs (SAP, Totvs, Oracle) or predictive maintenance software.

- This allows you to plan interventions based on actual parts consumption.

- It also makes it easier to cross-reference financial, logistics, and operational data.

With everything connected, MRO logistics transforms into a solid foundation for smarter, faster decisions focused on results.

Want to dive deeper into smart management of supplies, assets, and maintenance? See how other companies are using technology to gain total control:

- RFID in the Refrigeration Sector: Monitor everything in real time, ensuring full control over expiration and batch

- Cleaning Products Industrial and RFID: Total Control from Production to Distribution

- MRO Inventory in the Energy Sector: The First Step to Accurate and Scalable Management

How CPCON Group Turns MRO Inventory into a Competitive Edge

Imagine your trucking company with hundreds of trucks and several workshops. Each one controls its parts differently, without any standards or communication. When a truck breaks down, nobody knows where the right part is. The result? Losses, delays, and unhappy customers.

This problem is common, but it has a solution: CPCON Group.

With over 25 years of experience, we transform the mess of your parts inventory into a smart, easy-to-track system. We use cutting-edge technology (like RFID and sensors) so you know exactly where every part is, who used it, when they used it, and when to restock.

We’ve already helped large logistics companies quickly organize their MRO (maintenance, repair, and operations) parts inventories. This means less waste, standardized processes, and simpler audits, all without disrupting your daily operations.

We’re more than just a supplier; we’re your strategic partner. We combine technology and expertise to give you maintenance control that truly works: fewer idle vehicles, better performance, and complete organization.

For anyone in freight transport, managing parts can’t be an afterthought. With CPCON Group, this management becomes your competitive advantage, bringing efficiency, traceability, and quick decisions.

Ready to transform your fleet’s management? Talk to us!

Transforming MRO Logistics: Ensuring Control, Efficiency, and Growth

Accurately managing technical parts, tools, and supplies is no longer just a support task. In road freight transport today, MRO inventory is a strategic pillar for keeping your fleet active, cutting costs, and ensuring regulatory compliance.

Companies that master this management gain greater efficiency, fewer surprises, and a significant market advantage. And with the help of technologies like RFID and automation, you can move from improvisation to adopting a connected, intelligent maintenance control system ready to scale.

CPCON Group focuses precisely on this: turning the invisible into real control with solutions that integrate technology, data, and well-defined processes. For those looking to grow with security, productivity, and traceability, MRO in the logistics sector is the next step—and CPCON is the ideal partner for that journey.

FAQ

What does MRO mean in Logistics and how is it used?

MRO Logistics is all about managing materials used for fleet maintenance, repair, and operations. This covers everything from spare parts and tools to safety gear (like PPE) and other essential supplies that keep vehicles moving without unexpected stops.

What are the biggest risks of not having efficient MRO control?

Lacking proper MRO control leads to unplanned breakdowns, higher operating costs, wasted parts, and issues during audits. It also makes tracking difficult and can compromise the safety of your operations.

How does RFID technology improve MRO inventory?

With RFID, each item gets a tag that allows for real-time tracking. This eliminates manual errors, speeds up the management of your technical stock, and boosts visibility over the use of supplies and tools.

Can MRO inventory be integrated with a company’s ERP system?

Yes. CPCON Group’s solutions can be integrated with existing ERPs like SAP, Oracle, or Totvs, as well as maintenance systems. This ensures that MRO control becomes part of a unified and efficient operational flow.

How can CPCON Group help with MRO logistics management?

CPCON Group offers a complete approach, including technical mapping, automated identification (like RFID), system integration, and process standardization. This provides absolute control, reduces costs, and ensures compliance with industry standards.