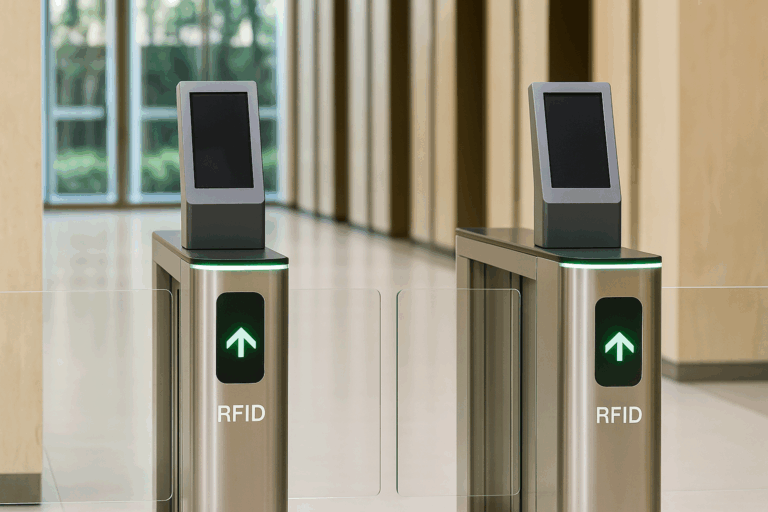

RFID Portal: a fixed structure with antennas and readers that identifies tagged products, people, or equipment in seconds and without line of sight, logging inbound/outbound movements in real time. In practice, it replaces spreadsheets and manual counts with continuous traceability, mass reads (UHF), loss reduction, and direct ERP/WMS integration for audit-ready compliance. If you need operational visibility, automated inventory, and data-driven decisions at shipping, receiving, or access control, the RFID Portal is the inflection point: higher accuracy, less rework, and standardized processes from shop floor to hospital.

This guide is for readers who want to know what it is, how it works, when to use it, and why it matters—with sector deep dives in healthcare, retail, logistics, and airports, plus cost, ROI, and implementation criteria. CEOs will find levers for growth and market trust; CFOs, metrics for CAC, ROI, margin, and predictability; CMOs, paths to marketing–sales integration and scalable programs; technical/operations leaders, gains in efficiency, standardization, and fewer handoffs. We also bring a real-world use case authored by Iasmim Godoy (Director of IT, CPCON) on smart access via NFC/QR Code and real-time RFID tracking at an ophthalmology institute, showing how the technology translates into safety, speed, and a better end-user experience.

Table of Contents

ToggleWhat is an RFID portal and how does it work?

An RFID portal is a fixed gate equipped with UHF antennas and readers positioned at chokepoints (docks, corridors, access doors) to automatically identify RFID-tagged items—products, equipment, or people—without line of sight and in real time. As items cross the defined read zone, each tag is captured and the event (inbound/outbound, movement, location) is logged in the management software, enabling continuous traceability, audit readiness, and direct ERP/WMS integration.

From hardware to software: components that close the loop

- RFID tag: stores the item’s unique ID; variants for metal, textiles, plastics, cardboard.

- Antennas + reader: emit/receive RF, apply anti-collision (avoids duplicate reads), and forward clean data.

- Middleware/Application: enforces business rules (“crossed = count”, “returned = reverse”), generates events, and integrates via API with ERP/WMS/BI.

- Orchestration: defines read zones and parameters (power, sensitivity, shielding) to keep accuracy high even at volume.

How a read occurs (step-by-step)

- A tagged item enters the portal’s read zone.

- Antennas energize the tag and capture its ID in fractions of a second.

- The reader performs filtering/anti-collision and packages the data.

- The software records the event (who/where/when), updating status, stock, or route.

- Data becomes available in dashboards/reports for decisions and audits.

Practical examples

- Logistics: at the dock, the portal registers shipping/receiving of pallets automatically, cutting discrepancies and accelerating invoice cut-offs.

- Healthcare: at controlled areas, wristbands with tags ensure patient location and safety. See the case: smart access via NFC/QR Code and real-time RFID tracking at an ophthalmology institute (CPCON) — authored by Iasmim Godoy (IT Director).

What each stakeholder gains

- CEO: operational predictability and market trust via fully traceable processes.

- CFO: improved ROI/CAC, fewer losses and manual inventories, tighter margins.

- CMO: consistent data for marketing–sales integration and clearer SLAs.

- Technical/Operations Director: standardization, fewer errors, shorter lead time, clean integration with legacy systems.

Which companies use an RFID portal and for what?

An RFID portal delivers the most value where movement is high and real-time traceability is critical. Below are the sectors with the most frequent adoption—with deep dives for each use case.

Healthcare

Hospitals, labs, and clinics use portals for access control, patient location, surgical kit tracking, and compliance.

Retail

Stores and distribution centers monitor inbound/outbound flows, inventory accuracy, and loss prevention; mass reads speed up replenishment and cycle counts.

Logistics and Manufacturing

Dock doors, corridors, and gates automate shipping/receiving, pallet/carton confirmation, and proof of passage for audits.

Airports and Carriers

Baggage and cargo control with fewer losses and full visibility across the journey.

What each stakeholder tracks

- CEO: market trust, scalability, contract growth

- CFO: ROI/CAC, margins, predictability (fewer losses, less rework)

- CMO: marketing–sales integration, consistent data and SLAs

- Technical/Operations Director: efficiency, standardization, fewer errors

What are the key benefits of an RFID portal?

Deploying an RFID portal upgrades control from manual and sample-based to automated, real-time, and at scale. Identification happens the moment items cross the read zone, cutting losses, compressing cycle times, and giving leaders trustworthy data for decisions.

Direct operational value

- Automatic, simultaneous reads of many items—no line of sight.

- Continuous traceability of inbound/outbound events and movement history.

- Fewer errors and less rework in inventories, receiving, and shipping.

- Faster audits with event logs ready to export.

- Clean integration with ERP/WMS/BI so data stays single-source-of-truth.

- Built-in scalability: start at a critical chokepoint and expand.

Where the value jump is highest

- Shipping/receiving: automatic pallet/carton confirmation and fewer discrepancies.

- Inventory accuracy: mass reads reduce downtime and manual counts.

- Access control and compliance: proof of passage and audit trails.

- Sensitive environments (healthcare/airports): location, safety, and end-to-end visibility.

What each stakeholder tracks

- CEO: predictability, contract scalability, market trust.

- CFO: ROI/CAC, shrinkage reduction, inventory cost, cost of non-compliance.

- CMO: product availability (avoids stockouts), consistent data for campaigns and SLAs.

- Technical/Operations Director: standardization, fewer human errors, shorter lead times, clean legacy integration.

Recommended KPIs to prove impact

- Inventory accuracy (%)

- Average receiving/shipping time

- Discrepancies per order/invoice

- Unlocated items per period

- Audit/compliance tickets

- Inventory cycle time

Best practices to capture the benefits

- Engineer the read zone first (power, antenna angle, shielding).

- Choose the right tags for the surface (on-metal vs. non-metal).

- Map processes and events into software rules (“crossed = post event”).

- Test integrations with ERP/WMS in a staging environment.

- Train the floor team to follow the new flow (no manual shortcuts).

How much does an RFID portal cost?

The investment in an RFID portal depends on environment, read volume, and integration depth. There isn’t a single price—there are ranges tied to structure (towers/antennas), number of read points, software, and implementation services.

What the investment includes

- Hardware: UHF readers, antennas, controllers, presence sensors, portal frame.

- Infrastructure & installation: network/power, mounting, cabling, shielding/barriers.

- Software: middleware, dashboards, licenses, and ERP/WMS/BI integration.

- Services: design, parameterization, testing, training, and support/SLA.

- Tags & consumables: on-metal/non-metal tags and, when applicable, printers/supplies.

Reference ranges (budget guidance)

- Single point / low volume: from BRL 20,000 (essential structure + basic software).

- Mid-size operation (2–4 points): BRL 40,000–80,000, typically with integration and dashboards.

- High throughput / multiple docks: BRL 100,000+, often with sensors, advanced orchestration, and extended SLAs.

Note: figures vary by layout, metal interference, antenna count, customization, and support contracts.

ROI and payback: how to demonstrate

- Where returns show up: fewer discrepancies and losses, faster inventory, fewer rework hours, less downtime in shipping/receiving, and higher accuracy (fewer stockouts).

- Baseline KPIs: inventory accuracy, average receiving/shipping time, discrepancies per order/invoice, unlocated items, audit/compliance tickets.

- Typical payback: 6–18 months, depending on volume, process adherence, and data integration.

How to implement an RFID portal (requirements, stages, and integration)

Adoption works best when you start focused, measure value, and scale safely. Below is a lean roadmap that reduces rework and accelerates ROI.

Project stages

- Diagnostics and flow mapping

Identify critical chokepoints (docks, gates, surgical areas), volumes, SLAs, and risks. - Read-zone engineering (RF design)

Define antenna placement/count, power, angle, and shielding to minimize interference and ghost reads. - Hardware and tag selection

Choose readers/antennas and surface-appropriate tags (on-metal vs. non-metal), rated for temperature and wear. - Infrastructure and security

Network, power, cabling, mounting, and EM protection; VLANs, logs, and role-based access. - Middleware and integration

Business rules (“crossed = post event”), APIs with ERP/WMS/BI, data normalization, and governance. - Controlled pilot (PoC)

Run at one point with clear success KPIs (accuracy, dock time, discrepancies per order/invoice). Tune RF parameters. - Rollout and training

Expand to new points; train operations, IT, and audit teams to avoid manual shortcuts. - Continuous monitoring

Dashboards, alerts, data hygiene, cycle counts, and semiannual parameter reviews.

KPIs to approve and scale

- Inventory accuracy (%) and unlocated items

- Average receiving/shipping time

- Discrepancies per order/invoice and audit tickets

- Portal availability (SLA) and duplicate-read rate

What each stakeholder validates

- CEO: predictability and contract scalability

- CFO: payback and impact on margin/working capital

- CMO: product availability and consistent data for campaigns/SLAs

- Technical/Operations Director: standardization, fewer failures, shorter lead time

RFID portal, fixed antenna, or RFID cabinet: differences and when to use each

Choosing the right setup prevents ghost reads, bottlenecks, and unnecessary cost. Here’s how RFID portal, fixed antenna, and RFID cabinet differ—and where each one shines.

RFID portal (lateral towers and sometimes a top antenna)

- Use when: high-throughput passages (dock doors, gates, corridors).

- Strength: reliable mass reads with proof of passage and audit-ready events.

- Watch-outs: requires careful read-zone engineering (power/angle/shielding) to minimize cross-reads.

Fixed antenna (no arch structure)

- Use when: moderate traffic at specific points—IT rooms, stockrooms, interior doors.

- Strength: discreet and cost-effective for continuous monitoring along a single axis.

- Watch-outs: narrower angular coverage; placement precision matters.

RFID cabinet (confined reading)

- Use when: batch verification of cartons/items with a fully controlled RF field (QA, sensitive picking, healthcare kits).

- Strength: very high read reliability with minimal external interference.

- Watch-outs: not a substitute for continuous-flow passages; it’s a checkpoint.

Handheld reader (complement)

- Use when: cycle counts, targeted sweeps, and exceptions.

- Strength: mobility and reach into hard-to-access areas.

- Watch-outs: human-dependent; not proof of passage.

Quick decision guide

- Continuous flow + proof of passage → RFID portal

- Specific spot, lower traffic → Fixed antenna

- Controlled check of closed kits/batches → RFID cabinet

- Exceptions and mobile inventory tasks → Handheld

Stakeholder impact

- CEO: staged scalability (start at critical docks, expand).

- CFO: optimized CAPEX (mix portals + fixed antennas/cabinets by risk/volume).

- CMO: better product availability (fewer stockouts from inventory errors).

- Technical/Operations: coherent zone design, less rework, stable SLA of reads.

RFID challenges and limitations (and how to mitigate them)

RFID success isn’t just antennas—it’s read-zone engineering + process + data. Below are the most common pitfalls and proven fixes.

1) Environmental interference (metal, liquids)

- Risk: signal attenuation/reflection; dead zones.

- Mitigate: on-metal tags, spacers, power/tilt tuning, physical shielding, supplemental antennas (overhead/floor), A/B layout tests.

2) Cross-reads and ghost reads

- Risk: capturing items outside the passage; inflated events.

- Mitigate: tighten the read zone (power, angle, shielding), EPC/location filters, anti-passback rules, minimum time between events.

3) Tag density and collision

- Risk: lower read rates at peak volume.

- Mitigate: Gen2 anti-collision tuning, channel balancing, distributed antennas, time windows aligned to conveyor/shift cadence.

4) Tag orientation and materials

- Risk: poor reads due to polarization or placement.

- Mitigate: application standards (orientation/position), dual-dipole tags, SKU test matrix before rollout.

5) Integration and data quality

- Risk: duplicates, latency, ERP/WMS inconsistencies.

- Mitigate: middleware with de-duplication, canonical IDs, idempotent events, async queues, latency monitoring.

6) Security and privacy

- Risk: unauthorized access, data exposure.

- Mitigate: VLAN segregation, RBAC, audit logs, in-transit encryption, reader hardening, retention policies.

7) Operational adoption

- Risk: manual “shortcuts” that break the flow.

- Mitigate: clear SOPs, role-based training (dock/store/IT/audit), visible floor KPIs, quick wins during the pilot.

8) Maintenance and durability

- Risk: performance drift from wear/adhesives.

- Mitigate: maintenance SLAs, spares, tags rated for temperature/abrasion, weekly checklists.

9) Scalability and cost control

- Risk: CAPEX growth without proportional return.

- Mitigate: start at critical points, standardize kits (portal/antenna/cabinet), reuse hardware, scale in KPI-guided waves.

10) Regulatory constraints (ANATEL/FCC/ETSI)

- Risk: out-of-spec power/channels.

- Mitigate: homologation, country profiles, periodic configuration audits.

CPCON solutions with RFID portals: from design to operations

CPCON delivers the full RFID cycle—from read-zone design to ERP/WMS integration and KPI follow-up—so your portal performs with precision from day one.

What we deliver

- Technical design: mapping critical flows, RF engineering of the read zone, and specification of antennas/readers/tags.

- Implementation: physical installation, network/power, power/angle tuning, and peak-hour stress tests.

- Integration: event rules in middleware (passage, reverse, exception) and APIs with ERP/WMS/BI.

- Assisted operations: role-based SOPs, training, and performance dashboards (read rate, first-pass yield, duplicates).

- Support & SLA: preventive/corrective maintenance, periodic parameter audits, and KPI-guided expansion waves.

Differentiators that shorten payback

- Multi-sector playbooks (healthcare, retail, logistics, airports) to reuse patterns that work.

- Data governance: canonical IDs, de-duplication, idempotent events—one source of truth.

- Compliance & security: operation within approved bands (ANATEL/ETSI/FCC), VLANs, RBAC, and audit logs.

- Scalability: standardized kits per passage point and an expansion roadmap tied to KPIs.

Proof in the field

- Smart access + real-time tracking at an ophthalmology institute (NFC/QR Code + RFID)—authored by Iasmim Godoy (IT Director).

- Additional results published: granite-block logistics with RFID and coffee agribusiness RFID deployment.

KPIs we track with you

Inventory accuracy, dock time (receiving/shipping), discrepancies per order/invoice, unlocated items, audit tickets, portal availability.

Ready to size your first read point? Request a technical assessment and receive a tailored read-zone design and rollout plan.

Conclusion

The RFID Portal isn’t an add-on; it becomes the backbone of operational control: automatic reads, real-time data, audit trails, and better decisions from receiving to shipping. When properly engineered (read zone, right tags, ERP/WMS integration), it cuts losses, speeds cycles, and lifts inventory accuracy.

With CPCON’s asset management and RFID expertise, you deploy an RFID Portal with solid RF design, clean integration, and data governance—shortening payback and gaining predictability. If your goal is efficiency, traceability, and scale, talk to our specialists and take the next step toward a smarter, safer operation.

FAQ

What is an RFID portal and what is it for?

A fixed gate with antennas and readers that identifies tags in real time as items cross the read zone. It replaces manual counts with continuous traceability and automatic inbound/outbound event logging.

How does it differ from a fixed antenna or an RFID cabinet?

A portal covers high-throughput passages and provides proof of passage. A fixed antenna monitors a specific spot with lower traffic. A cabinet performs controlled batch verification; it’s a checkpoint, not a continuous flow.

Where does an RFID portal deliver the most impact?

At shipping/receiving docks, logistics corridors, healthcare access points, and any high-volume operation. Benefits include fewer discrepancies, faster inventory, and audit-ready data.

How much does it cost and what’s the typical payback?

Costs vary by number of points, environment, and integration. Projects often start around BRL 20,000 and can exceed BRL 100,000 for large sites. Typical payback ranges from 6 to 18 months depending on volume and process adherence.

How do I start with low risk?

Pick a critical chokepoint, run a pilot with clear KPIs (accuracy, dock time, discrepancies), tune the read zone, and integrate with ERP/WMS. Then scale in KPI-guided waves.

An RFID Portal identifies tags in real time without line of sight, automating inbound/outbound events, inventory counts, and access control with continuous traceability and ERP/WMS integration. This guide covers what an RFID Portal is, how it differs from fixed antennas, cabinets, and handhelds, the benefits (accuracy, shrinkage reduction, audit-ready logs), priority use cases (healthcare, retail, logistics, airports), and challenges with mitigation tactics. It includes budget ranges (from BRL 20k to 100k+), KPIs, and a real-world ophthalmology case, plus an implementation roadmap and stakeholder mapping (CEO, CFO, CMO, Operations). CPCON provides end-to-end design, integration, and assisted operations to shorten payback (6–18 months) and scale confidently.