What comes to mind when we talk about IT asset tagging best practices? Imagine a critical server failure: time is ticking, but no one knows where the equipment is, who is using it, or its maintenance history. Extreme? Unfortunately, this is a reality for many companies.

At the heart of this vulnerability is the lack of a structured asset tagging process. More than just logistics, it’s a pillar of IT governance and a strategic approach for sustainable growth. Companies prioritizing control, efficiency, and security start here. IT asset tagging isn’t just about labeling—it’s about ensuring visibility, traceability, and smarter decisions. In this article, we’ve compiled everything you need to adopt an effective strategy: what it is, why it matters, and how to apply IT Asset Tagging Best Practices consistently and securely.

Table of Contents

ToggleIT Asset Tagging Best Practices: What Is?

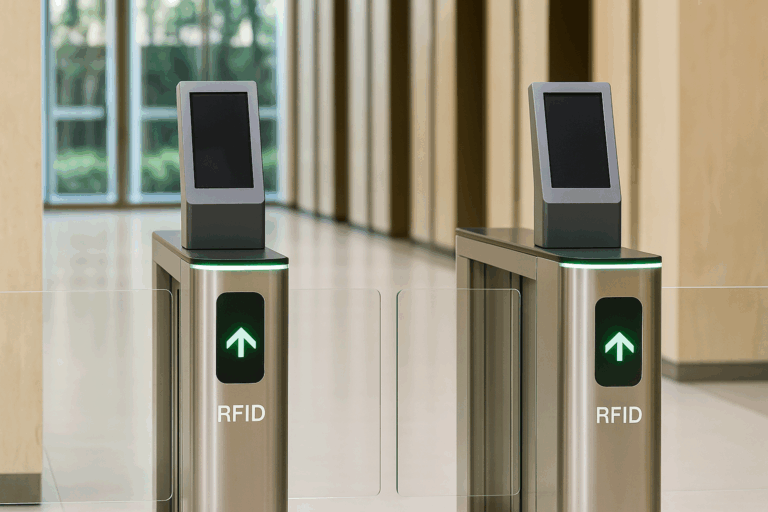

IT asset tagging is the process of physically identifying all technological equipment and resources within an organization. This identification typically uses barcode labels, QR codes, or RFID tags, linked to a centralized asset management software. The goal is to ensure traceability, visibility, and control over items such as:

- Computers, laptops, and servers

- Monitors and peripherals

- Mobile devices

- Routers, switches, and other network components

- Remotely allocated assets (in branches or home offices)

Beyond operational necessity, tagging is the starting point for building a reliable inventory and maintaining an up-to-date asset database—essential for strategic and secure decision-making.

Why Is Asset Tagging Important?

Asset tagging is directly linked to operational efficiency, regulatory compliance, and financial risk reduction. Key benefits include:

- Complete Visibility of the IT Infrastructure: Knowing exactly how many assets exist, their locations, users, and conditions is crucial for intelligent planning of purchases, replacements, and upgrades.

- Reduction of Losses, Misplacements, and Fraud: Without a tagging and traceability system, assets can easily go missing or be misused. A structured management approach helps detect and prevent physical and accounting losses.

- Support for Governance and Auditing: Companies subject to audits need reliable data on their assets. Tagging facilitates physical-accounting reconciliation and adherence to standards like SOX, IFRS, and ISO.

- Optimization of Maintenance and Lifecycle Management: Integrating tagging with an asset tracking system (EAM, CMMS, or ERP) allows tracking each item’s history, scheduling preventive maintenance, and reducing downtime.

- Strategic Decision-Making: With updated and organized data, IT can act more strategically—from investment prioritization to cybersecurity risk management, procurement planning, and alignment with ESG goals.

How to Implement Asset Tagging Effectively?

Implementing effective asset tagging involves planning, standardization, appropriate technology, and involvement from responsible departments. Key pillars include:

Define a Standardization Strategy

Standardize label formats, coding, and numbering logic. This facilitates future management and avoids redundancies.

Choose the Right Technology

Selecting the right identification technology is a pivotal step towards efficient IT asset tagging. Each option – barcode labels, QR codes, and RFID tags – offers distinct features tailored to various needs and environments.

Understand the specific characteristics of each to choose the solution that best aligns with your operations.

- Barcode Labels: Low cost, simple reading, ideal for controlled environments.

- QR Codes: More data in less space, allowing redirection to systems.

- RFID Tags: Radiofrequency reading, ideal for large volumes and industrial environments.

Use Durable and Resistant Labels

Invest in labels that withstand the conditions of the environment where the asset will be used (temperature, humidity, handling). Inadequate materials can quickly deteriorate, compromising traceability.

Integrate with Asset Management Software

Tagging should be connected to a system that centralizes asset information, allowing easy queries, updates, and audits. Ideally, this system integrates with the company’s ERP or CMDB.

Train Involved Teams

Process adherence depends on the engagement of those executing it. Train IT, asset management, operations, and facilities teams to understand the value of tagging and how to properly register assets.

Regularly Review the Inventory

Tagging assets is just the beginning. Management should include periodic reviews (annually, semi-annually, or as needed) to ensure the asset database remains reliable over time.

From Chaos to Control

IT Asset Tagging Best Practices may seem straightforward in theory but are powerful in asset management routines.

When well-executed, they transform chaos into clarity, strengthen governance, and support safer, smarter decision-making.

Companies treating tagging merely as an operational obligation miss the opportunity to view their assets with the depth and control required—ultimately impacting business performance.

If your organization seeks efficiency, security, and strategic IT vision, start at the foundation. Start with tagging.

Simplify IT asset tagging and achieve total visibility: CPCON offers the best solutions for you! Contact us to learn more.

FAQ

What is IT asset tagging?

It is the process of physically identifying the company’s equipment and technological resources using labels with barcodes, QR Codes or RFID, connected to an asset management system.

Why is asset tagging so important?

It guarantees visibility, traceability and control of assets, reduces losses, facilitates audits and supports strategic decisions in the IT area.

What technologies can I use to mark my assets? ️

Barcodes (low cost, easy to read). QR Codes (store more data). RFID (contactless reading, ideal for large volumes).

How do you ensure that the marking is durable and efficient?

Use tags that are resistant to the environment in which the asset will be used and integrate the process with an asset management system, such as ERP. It is also essential to train the teams involved.

How often should I review my IT inventory?

The recommendation is to carry out periodic reviews (annually or biannually), depending on the criticality of the assets, to keep the database up to date and reliable.