How RFID tags increase visibility for inventory management is no longer a secret. These tags provide instant, accurate stock counts, eliminating manual errors and ensuring top-tier inventory precision. With real-time visibility and bulk reading capabilities, it’s clear why leading retailers are making the switch.

This isn’t just about technology; it’s about staying ahead in the game. Read on to unveil the magic behind the scenes.

Table of Contents

ToggleKey Points

- Enhanced Inventory Accuracy: RFID tags deliver instant and precise stock counts, drastically reducing manual errors and improving inventory accuracy.

- Real-Time Visibility: With bulk reading capabilities, RFID tags provide unprecedented visibility, allowing for real-time monitoring of every item in the inventory.

- Inventory Management Optimization: RFID technology streamlines inventory management processes, from receiving to shipping goods, by automating item counting and locating.

- Enhanced Tracking Efficiency: RFID technology not only optimizes inventory accuracy but also enhances the tracking of items throughout the supply chain, providing real-time updates and history of item movement, which complements overall inventory management and customer satisfaction.

- Operational Cost Reduction: By eliminating the need for manual counts and reducing inventory errors, RFID tags can significantly lower operational costs.

- Reduced Labor Costs: Automating inventory tasks such as cycle counting or stock checks with RFID technology can significantly free up staff time, leading to labor cost reductions.

- Improved Customer Experience: The improved inventory accuracy afforded by RFID tags aids in better order management and product availability, leading to a more satisfying shopping experience for customers.

Exploring the Impact of RFID Tags for Inventory and Tracking

The adoption of RFID Tags for Inventory management is revolutionizing how businesses track and manage their stock. This cutting-edge technology offers a seamless, efficient solution for inventory challenges faced by many industries today.

Why RFID Tags for Inventory Control Stand Out:

- Improved inventory accuracy: RFID tags can help businesses to track their inventory more accurately by providing real-time data on the location and status of their items. This can help to reduce stockouts and overstocks.

- Instantaneous Tracking: RFID tags allow for the immediate identification and tracking of inventory items, streamlining operations and enhancing logistical efficiency.

- Error Reduction: The precision of RFID technology significantly reduces the likelihood of errors, ensuring that inventory records are always accurate and reliable.

- Easy Integration: RFID systems can be effortlessly integrated with existing ERP or WMS platforms, providing a cohesive overview of inventory levels and movements.

- Scalability: As businesses grow, the scalability of RFID technology means that it can expand to meet increasing inventory management needs without substantial additional costs.

- Sustainability: With RFID tags, companies can achieve a more sustainable inventory management process by reducing waste associated with manual errors and optimizing stock levels.

However, there are also some challenges associated with using RFID tags for inventory:

- Upfront cost: The initial investment in RFID can be higher than barcodes due to the cost of tags, readers, and software infrastructure.

- Read range: The read range of RFID tags can be limited by factors such as the type of tag, the material of the item being tagged, and the presence of other RFID tags.

- Integration: RFID systems can be complex to integrate with existing business systems.

Return on investment (ROI): In the long run, RFID generate a positive ROI by reducing operational costs in areas such as:

- Inventory: RFID can improve inventory accuracy, reducing shrinkage and optimizing stock management.

- Manufacturing: RFID can automate production tasks such as part tracking and quality control.

- Logistics: RFID can streamline the transportation and delivery of goods, reducing errors and delays.

- Retail: RFID can enhance the customer experience by enabling contactless payments and self-checkout.

RFID Tags for Inventory are not just a technological upgrade; they represent a strategic investment in the future of inventory management. By embracing this technology, companies can enjoy a competitive edge in efficiency, accuracy, and customer satisfaction.

How much rfid tags for inventory cost?

A complete RFID solution consists of hardware (antenna, handheld readers, rfid readers, etc.), software, and the RFID Tags. The hardware component encompasses the RFID equipment like antennas, readers, wi-fi, portals, while the software and systems integrate the reader and data collection abilities to dashboard or interfaces.

Generally, in the United States, the cost of an RFID tag can vary from 25 cents to 1 dollar each tag. RFID Systems and softwares are often priced on a subscription basis.

RFID tags can definitely impact your inventory costs, but it’s a two-sided coin. Here’s a breakdown:

Upfront Costs:

- Tags themselves: These vary depending on the type you need. Passive tags for basic inventory management can be very cheap, around $0.10 to $0.20 each, and even lower in bulk [cost of rfid tags]. But more complex tags with longer read ranges or special features can cost several dollars.

- RFID readers and scanners: These are specialized pieces of equipment that cost anywhere from $700 to $3,000 or more depending on features and range [RFID scanner cost].

- Software: You’ll likely need software to manage the data collected from your RFID tags. This cost can vary depending on the complexity of your system.

Potential Cost Savings:

- Reduced labor costs: RFID can automate many inventory tasks like cycle counting or stock checks, freeing up staff time.

- Improved accuracy: RFID provides real-time data on your inventory, which can help reduce errors and shrinkage.

- Lower stockouts: With better visibility into stock levels, you can reorder items before they run out, avoiding lost sales.

- Theft prevention: RFID tags can be used to track high-value items and deter theft.

Overall Impact:

Whether RFID saves you money in the long run depends on your specific situation. Here are some things to consider:

- The size and value of your inventory: RFID makes more sense for businesses with large or expensive inventories.

- Your current inventory management practices: If your current system is inefficient or error-prone, RFID can offer significant improvements.

- The potential cost savings: Weigh the upfront costs of RFID against the potential cost savings from improved accuracy, reduced labor, and lower shrinkage.

It’s a good idea to carefully evaluate your needs and costs before implementing an RFID system.

What is RFID technology?

RFID ( Radio Frequency Identification) technology transmits data and information by radio frequency.

RFID has become popular and is increasingly used in various segments. That’s mostly because the use of RFID technology provides sightless long-distance reading capabilities. This can be widely apply to generate efficiencies and automate inventory cycle counting.

How does the RFID system work?

The main characteristics of the RFID system go as follows:

- Antenna is responsible for transmitting the information to the reader. This RFID antenna can be either fixed or handheld.

- A reader will be receiving data from the antenna and converting it into radio waves;

- RFID tag contains a chip to respond back to the radio waves

What is the RFID tag?

RFID tags contain a radiofrequency chip, which is responsible for responding to radiofrequency stimulus coming from antennas. To track and monitor changes in inventory, RFID tags and labels can be applied to metal and non-metal objects.

How does RFID work for warehouse inventory management?

By applying the RFID tag to each inventory item or pallets, any changes in item’s movement and quantity can be verified by the antennas and readers. The RFID system and software can display and match information on a dashboard platform integrated with an existing ERP or WMS system, allowing warehouse associates to reconcile and report inventory data in real-time. The company may track and manage the entire inventory cycle from item’s inception until its delivery to the final customer.

How do RFID tags work?

RFID tags are also known as Smart Tags, which is a label that can electronically read items in bulk and store data. Another functionality of the RFID tags is to send locational info of the tagged objects. Common technologies existed in RFID Tags includes the microchip and the EPC format. While the microchip emits radio frequency waves – read by the RFID antennas -, the EPC format stores data in unique identification code (hexadecimal) known EPC.

Microchip

The microchip in RFID tags store data and information about an item, such as:

- Product Name

- Expiration Date

- Plot

- Serial number

- Company

- Manufacturer

- Item’s Picture

- Documents and warrants

Along with the data storage function, the microchip also responds back to radio frequency stimulus transmitted by antennas and readers.

EPC format

RFID tags store data in EPC format, Electronic Product Code. This technology was created by the Auto-ID Center to replace the barcode identification. EPC is a low-cost method of tracking items while using RFID technology. Like barcode, the EPC format displays a numeric system to identify and register products. Though it has a much greater capability than its predecessor in adding specific information, such as product origin and destination. One of the benefits is that EPC comes with a unique identification code format. This means that EPC in RFID Tags can prevent counterfeit items, as consumers can also monitor and track their products traced back to purchase with the supplier.

Amazon Go’s Case of RFID Tags In Stores

Amazon Go is an online store that differs from the other typical stores, since there aren’t cash registers and lines. The customer installs the Amazon Go app to choose items and pick up them at the store, while paying it via the app itself.

RFID system tracks and updates the item’s moments and information, as customers check out or return items, as well as updating the products to the customer’s virtual cart in real-time. All the store’s products are tagged with RFID tags for inventory management, while enhancing the company’s competitive strategy.

Through this RFID system, the store managers and associates are able to keep track of the stock levels, reconciliation and each item’s location. This provides information and inventory reports, followed by the bulk scans of items with RFID. Additionally, detailed database with the item’s movement (check in/out) history and logs.

What is the difference between active RFID tags and passive RFID tags?

Passive RFID tags does not contain an internal battery to send the radio waves, like the active one. That means that this RFID tag can only be scanned and read by using an antenna – either fixed or handheld – and reader.

On the other hand, active RFID tags come with an internal battery to constantly emit radio waves, offering a longer read range and real-time connection. Often, active RFID tags are more expensive and complex than passive RFD tags. Both RFID tags are widely used for inventory tracking.

What are the types of RFID tags?

RFID tagging solutions depend on each application:

- RFID inventory labels (off-metal) can be applied to boxes

- RFID stickers can be applied to inventory products, so that customer can scan it and learn more information about the product

- RFID washable tags can be applied / sewn-in associate’s clothing to keep track of the item’s custody and movement

- RFID access cards can be used to control the access of people and vehicles in parking lots and companies, along with biometric readings.

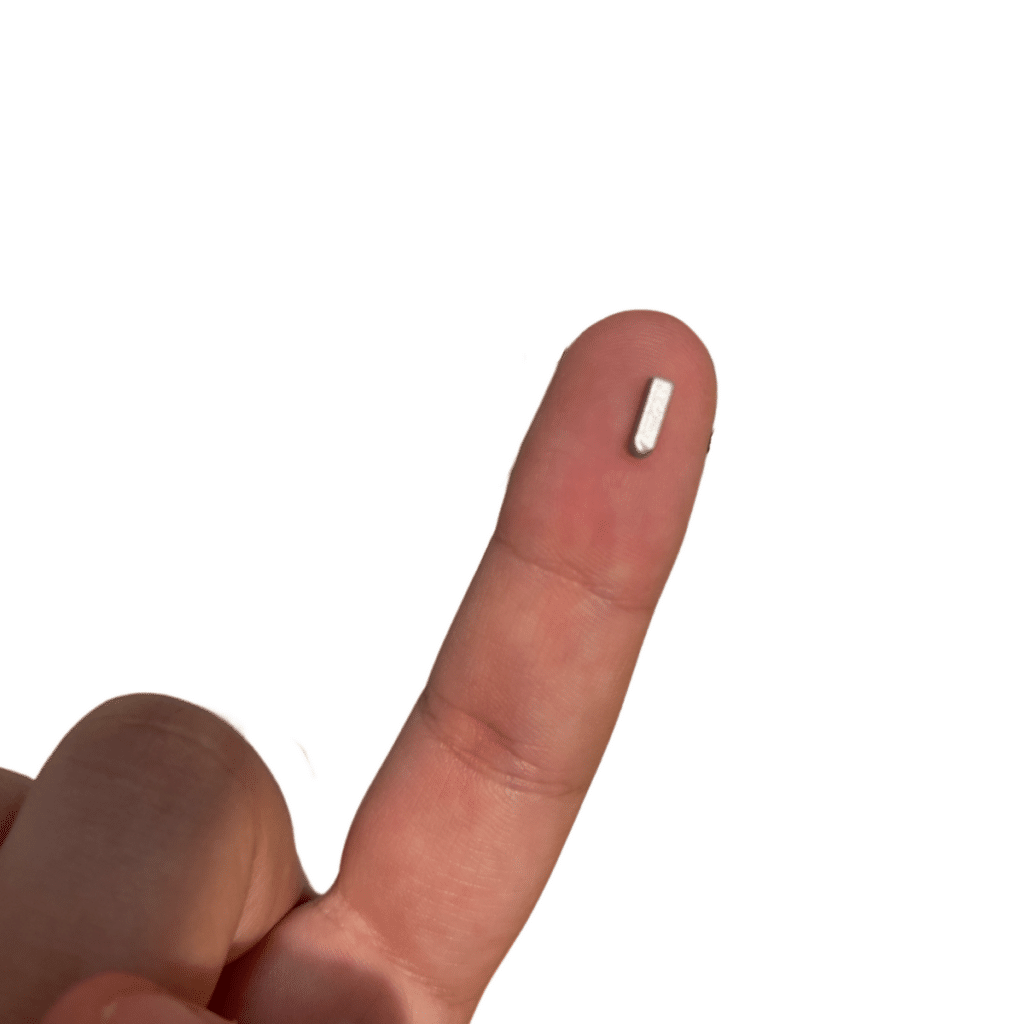

What is the size of RFID tags?

The size of RFID tags can vary, but, in general, these are small objects. Tag dimensions will vary according to the purpose and type. For instance, RFID cattle ear tags for animal identification tend to be very small, with a dimension 0.12” x 0.40” (inches), while RFID cards for access control typically will be over 2 inches high.

FAQ’s

What are RFID tags used for in inventory management?

RFID tags provide real-time tracking of items, ensuring accurate stock counts and efficient inventory management.

How do RFID tags differ from traditional barcodes?

Unlike barcodes, RFID tags can be read in bulk without direct line-of-sight, speeding up inventory processes and reducing manual errors.

Why are top retailers switching to RFID for inventory?

RFID offers superior visibility, accuracy, and efficiency, making it a preferred choice for inventory management among leading retailers.

Can RFID tags store additional data about products?

Yes, RFID chips can store details like item pictures and vital information, enhancing product tracking and data accessibility.

How do RFID systems integrate with other business systems?

RFID systems can seamlessly integrate with ERP or WMS systems, ensuring synchronized inventory data across platforms.

Unlock Superior Inventory Management with CPCON: Your RFID Technology Partner

Looking to transform your inventory management with RFID technology?

At CPCON, we’re dedicated to helping businesses like yours achieve unparalleled efficiency and accuracy. Don’t get left behind in the inventory race. Contact CPCON today and let’s take your operations to the next level.

Need guidance? We’re here to assist!